Easy ways to reduce shop injuries and improve technician health

In our recent coverage, we've had several sources tell us that too many shop leaders treat technician health and wellness as an afterthought. That might not be the whole truth, but it is the perception. And we know how utterly complex and exhausting working in fleet repair shops can be, so we wanted to make this aspect a lot easier for managers to address.

We turned to a Dr. Mark Ciolek, a consulting physical therapist with workplace health services company Pro-Activity, to help fleets better understand how prevalent these issues are and how to solve them. Dr. Ciolek has spent the past five years working with various fleet groups servicing anything from lawn mowers to heavy equipment & cranes.

Fleet Maintenance: What made you focus on therapy for trade workers?

Mark Ciolek: Working in traditional physical therapy settings you quickly realize you’re missing a large portion of individuals who could use your help sooner. Trade workers are a perfect example of this, many of them ‘getting through’ each day carrying various health issues along with them. I joined Pro-Activity’s team to begin bringing resources directly to the people on the ground doing physical work.

FM: Making sure a tech knows proper lift operation will help keep a vehicle from falling on them, but what are some less obvious risks in the shop regarding long term health?

MC: A large portion of fleet techs will be limited not by traumatic events, but more from simple aches and pains that develop over time. Our ability to notice the warning signs of decreased fitness, strength, and mobility is as important as a check engine light. Doing preventative maintenance early to keep the body running well is one of the best things you can do to keep healthy.

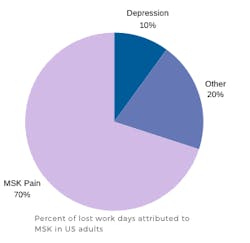

It's also important to note that 70% of lost work days have been attributed to musculoskeletal pain.

FM: Do the fleet managers you talk to generally have workflows in place to keep techs’ health and wellness maintained, or is this less thought about?

MC: Fleet managers aren’t health and wellness experts, but maybe that’s okay. The truth is, for a busy shop the simple things can go a long way. Even small mindset shifts that bring attention to worker health, even in small ways. For example, “Can we start the day with a warmup?...Make sure you have a kneeling pad….Let’s get some fruit & salad with the lunch order today.”

Just like you have a system for process improvement in other job workflows, considering what injury risk a job might pose and how to control it is a great starting point.

FM: What are some specific examples of how you’ve gone in and helped a commercial vehicle repair operation to improve technician health?

MC: Here are some examples of real people:

- Mechanic 1 - Seasoned tech who can’t do overhead lift work because his hands get numb

- Mechanic 2 - Still young, but his back flares up doing work over the engine

- Shop Supervisor 1 - Health declined since moving to management & feeling burnt out

All three of these are real people in a NYC shop dealing with issues that limit them. Like most fleet shops they did not have an organized health & prevention program. This shop and their organization engaged in all aspects of a musculoskeletal health initiative. Learning how to better prepare for work (morning movement priming), examining how to reduce the load they are under (tool use & ergonomic position), addressing aches and pains early (physio consults), and improving the conditions of their working body (health strategies).

Mechanic 1’s numbness nearly completely resolved. Mechanic 2 calmed his back pain and found solutions for tolerating engine work better. Shop Supervisor 1 started adding walks at lunch and gradually adding health eating like smoothies. In large groups that include fleet operations we’ve seen injury reductions of 75% over 10 years.

FM: With the tech shortage, shops can ill afford to have a tech go down with a severe injury. After making sure that tech is being taken care of medically, what else should management do in terms of load management for other techs and helping ease a hurt tech back to work?

MC: When we look at load management in athletes, fatigue and injury risk increases with workload spikes around 30-50% more than the prior weeks. While some may tolerate more, being strategic about how you spread the work timelines out or share between techs can help reduce injury risk during a transition.

Close communication with employees on early fatigue risk signs is important and can allow for readjustment on the fly. The same rules apply for return to work. The longer the absence, the more gradual the on ramp back to work. Lean on rehab professionals with experience in the trades here.

FM: Do you deal with mental health/stress? For workers and leaders who aren’t balancing tires and changing brakes, but working on crunching numbers and multitasking myriad repairs, this seems like a big health risk. Any advice to make sure they are taking care of themselves?

MC: While not all stress is bad, when the daily grind begins to overwhelm beyond what you can handle it’s important to take steps to address it. Again, health changes that are small and consistent beat dramatic but short lived. Where can you start?

- "Movement Snacks" are a stress sponge: Walk, stairs, chair squats, anything that gets the

heart pumping. - Mind the Inputs: Diets with more fruits and veggies with less processed foods are linked to handling stress better.

- Sleep to Reset: Like a car wash for the brain, sleep flushes the brain and allows it to start fresh.

FM: Any final words of advice or guidance?

MC: At Pro-Activity we place heavy emphasis on five “ELEMENTS" (3 specific actions + 2 broad influences) which are the most widely validated to improve health.

MOVE - Does your body move like it should, freely, & without pain?

FUEL - Are you eating foods that promote health? Quality matters.

RECOVER - Are you consistently getting enough rest to repair from the day & thrive?

ENDURE - Resilience is a skill & a practice that allows us to thrive in challenges.

CONNECT - Surround yourself with the right team, it impacts our health.

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.