Roadside breakdown costs continue to increase

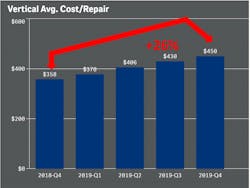

FleetNet America announced unplanned roadside maintenance costs have increased 26 percent in the fourth quarter of 2019. This is the fourth consecutive quarter of increased roadside maintenance costs reported from the TMC/FleetNet Vertical Benchmarking Program.

Jim Buell, executive vice president for sales and marketing at FleetNet America, shared insights from the latest quarterly benchmarking report, which monitors unplanned roadside breakdowns and repairs for participating fleets. The findings were shared during a press conference at the Technology & Maintenance Council's Annual Meeting and Expo in Atlanta.

"The cost of completing an unscheduled roadside repair is increasing," Buell said. He advised there are three notable reasons for this: increased labor rates because of the technician shortage, longer repair times and more towing events due to the added complexity of newer equipment, and an increased parts cost partially due to tariffs.

Benchmarking to improve maintenance practices

"All too often, people in our industry tend to think of roadside repairs as like death and taxes: 'It just happens, you deal with it.' You try and get the best rate," Buell says. He argues that all participating fleets in the same operation vertical - whether that be truckload, less-than-truckload, or tanker presently - have the opportunity to see how the mileage between breakdowns for the best performing fleets in each category. "If you've got one truck locally that can run 41,000 miles between a breakdown, why can't everyone in the truckload vertical do that? The vertical benchmarking program gives [fleets] the tools to identify where they can find those improvements."

"There is a wide variance between the performance of the average fleet and the best-in-class carrier in each vertical," Buell said. "This is a pretty good indication that our industry has room to reduce maintenance costs by closing the gap between the average and best-in-class fleets."

Tanker is the most recent segment added to the program, which notably had a higher level of roadside breakdowns. Buell noted that when new fleets are added, it can skew results as they are setting their benchmark before taking on new ways to improve maintenance.

The Vertical Benchmarking program is a TMC member benefit allowing participating fleets the opportunity to opt in and share roadside repair data. It is critical that the fleets pursue the following rules when submitting this information: It must be VMRS coded, all roadside breakdowns must reported, IFTA fueling mileage is required, and must participate for the full quarter.

Five vehicle systems - coded via VMRS - account for 65 percent of all roadside repairs experienced by participating fleets in the fourth quarter of 2019. These categories include tires, brakes, lighting, power plant, and cooling systems.

"Pay attention to those five (categories) and find ways to improve in those and you will find a way to make an improvement to your business," said Buell.

Recent enhancements , future plans

An upgrade to the interface and dashboard for users, which allows for a simplified view, or "snapshot," and ability to drill down into detailed information. It also provides participants an overview of their top five repair categories, comparing that information to their vertical's top five repairs.

"One thing none of us have is time," Buell said. "I hear from customers that they all want information, but they don't have time to do the analysis. We have set this up with the intent that a fleet leader could take a look at this this information and in about 30 minutes a quarter, identify opportunities to make improvements in their operation."

Additionally, Buell advised TMC and FleetNet plan to hold an operators forum in the summer of 2020 to allow best-in-class fleets to share their best practices for vehicle maintenance and service.