Marketability and serviceability of last-mile delivery vehicles

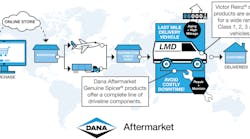

More and more companies are shifting away from single trucks delivering large shipments to a central location to delivering packages directly to the end-users with vans and smaller trucks. This final step in the delivery process is called last-mile delivery (LMD) and refers to the short route to the final delivery destination.

With a dramatic rise in recent months of last-mile deliveries due to social distancing and stay-at-home orders, downtime is almost inevitable for these LMD delivery vehicles due to the increased stress placed on all vehicle systems by stop-and-go driving, higher mileage, and extended idling periods of in-town delivery service. Downtime of LMD vehicles costs owners more than just the price of the repair, so getting these vehicles back on the road quickly with quality parts is essential.

If repair facilities are not already experiencing an influx of LMD vehicles that will need service and repair, they likely will. This will not be a short-term situation as evidenced by the dramatic increase in the number of LMD vehicles on the road, such as the Mercedes Sprinter, Ford Transit, and Nissan NV. In 2019, there were over one million of these vehicles in operation, growing five-fold from roughly 200,000 in 2014.

Fleet managers and repair shops need to be prepared for what promises to be a substantial increase in service and repair opportunities related to these vehicles. Being proactive and having a plan to meet potential service demands will be imperative if shops want to keep these much-needed vehicles in proper working condition.

Since last-mile delivery vehicles can experience added wear and tear due to extended use in stop-and-go and severe driving conditions, it is always important to inspect the driveline at every service interval. Identifying components that have begun to fail can be done through routine inspections for items like the driveshaft end play and worn u-joints.

In order to reduce downtime and get these delivery vehicles back on the road quickly, it is vital to have access to quality replacement parts and accessories that are easy to install and have the fit, performance, reliability, and durability of original equipment.

One way fleet managers and repair shops can help decrease downtime is by installing parts that are virtually maintenance-free and offer a one-for-one replacement. An example that can help lessen the stay-in-the-bay for a Mercedes or RAM Sprinter van is the Spicer three-piece driveshaft. Because Dana pre-balances its Spicer driveshafts, a technician can perform a driveshaft replacement quickly and efficiently without the need for a balancing machine. The ability to swap out the driveshaft improves shop profitability by saving valuable service time and significantly reducing vehicle downtime.

In addition, if the Sprinter van driveshaft needs servicing down the road, the u-joints are serviceable, not staked. Driveshafts for Sprinter vans like those from Spicer minimize assembly time and meet global aftermarket driveshaft requirements, providing an optimal replacement solution, particularly for service shops with immediate uptime service programs.

Gaskets are also critical for fleet managers to have on hand to address a failure immediately, reduce downtime, and prevent further damage to vehicle systems. When rebuilding an engine, it is important to have every component required to make the repair on hand, eliminating the need to research each different part and source them across a variety of manufacturers.

A valuable solution for fleet managers seeking fast and efficient service options are complete gasket sets, like those from Victor Reinz, with coverage available for a range of Class 1, 2, 3, and 4 vehicles and offerings that include conversion gasket sets, cylinder head gasket sets, and turbocharger mounting kits for vehicles like the Sprinter van. With complete gasket kits, repair facilities will have all of the components in one box so they can perform repairs quickly and efficiently.

Fleet managers may find a shift within their fleet mix that places more emphasis on these versatile vehicle platforms, resulting in different service component purchasing patterns. Having the ready-to-install parts on hand to service LMD vehicles will be paramount to facilitate service productivity, decrease costly downtime, and improve shop profitability.

Beth Grime-Mooney is known for building marketing capability through program design, and influence through customer-centric activation. Beth has been studying customer needs throughout her career tenure at ITW, Sherwin-Williams, Honeywell Bendix, Eaton, Tenneco, and Dana, as well as overseas at Opel Automobile GmbH in Frankfurt, Germany. Follow Beth on LinkedIn at linkedin.com/in/bethmmooney