Bendix adds testing option to 2022 technical training

Bendix Commercial Vehicle Systems has announced its schedule of 2022 technical training sessions to upskill the CV industry on air brakes and advanced technology. These will include in-person opportunities in 11 states, as well as virtual training opportunities—with a new testing option for each. The sessions are open to fleet technicians, owner-operators, and others to enhance their maintenance skills necessary for the superior uptime and safety.

“From our partners throughout the industry, we understand the need for comprehensive, convenient training—made even more urgent by the technician shortage—and we are committed to helping meet that need,” said Lance Hansen, Bendix vice president – aftermarket sales, fleet, service, and field operations. “These men and women operate in a fast-changing commercial vehicle landscape, where safety components evolve rapidly—and where carriers face intense pressure to maintain overall safety, performance, and uptime while striving to lower their total cost of ownership.”

Every class is conducted by a member of the ASE-certified veteran Bendix Service Engineering Team. Registrants may elect to take part in a written test administered at the close of each class. Bendix will grade the exam, and registrants earning a passing grade will receive a Tested and Passed Certificate. Those who take the exam and don’t pass will receive a Certificate of Completion, as will registrants who elect not to participate in the optional testing. In-person Bendix training and the optional test are not affiliated with the U.S. Department of Transportation (DOT). It does not take the place of any instruction or certification exam administered by the DOT.

Training options, testing opportunity

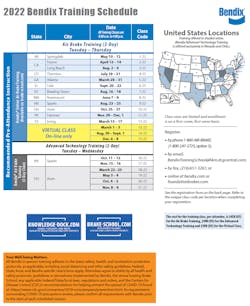

Air Brake Training sessions: There will be12 three-day Air Brake classes, beginning March 15-17 in Irving, Texas.

Advanced Technology Training: Bendix will provide six two-day in-person program, which launched in 2019. Four sessions will be held at the company's new headquarters in Avon, Ohio, with the first on March 22-23. Two others will be at the company’s Sparks, Nevada, location.

Virtual Air Brake Training: These three-day training events begin March 1-3.

Registration is open for the complete schedule of both courses.

All in-person training adheres to the latest safety, health, and sanitization protection protocols, as applicable, including social distancing and other safety guidelines. All federal, state, local, and Bendix-specific restrictions apply.

Safety curriculum

Bendix’s three-day Air Brake Training class is tailored to both new and experienced technicians, and covers the description, operation, and service elements for the total range of components found within dual air brake systems. Classroom topics include the fundamentals of compressed air; tactics for air system failure mode diagnosis and troubleshooting; and components such as air compressors, valves, foundation drum brakes, air disc brakes, and steering.

Bendix recommends that each participant complete the online air brake training at the company’s brake-school.com site before taking the in-person Air Brake Training.

The two-day Bendix Advanced Technology Training class covers the operation and troubleshooting of higher-level driver assistance and safety systems, as well as diagnostic software.

Sessions will address:

- Antilock Braking Systems (ABS)

- AutoVue Lane Departure Warning (LDW) System from Bendix CVS

- Bendix ESP Electronic Stability Program

- Bendix Wingman Advanced – A Collision Mitigation Technology

- Bendix Wingman Fusion driver assistance systems

- SafetyDirect system by Bendix CVS

- SmarTire and SmarTire Trailer-Link TPMS by Bendix CVS

- Active Steering by Bendix.

The Advanced Technology Training program includes hands-on, in-depth maintenance instruction for Bendix air disc brakes and electrical diagnostics.

“This class is a must for advanced technicians as more fleets adopt complex technologies like collision mitigation systems and continue to rapidly expand their use of air disc brakes,” Hansen said.

Because of the quantity and complexity of the products covered, Bendix strongly advises each student to complete either the three-day Air Brake Training course or, at a minimum, the online air brake training at brake-school.com before taking the Advanced Technology Training class.

Per-person enrollment costs are $450 USD for Air Brake Training, $400 USD for Advanced Technology Training, and $300 USD for the Virtual Class. Enrollment is on a first-come, first-served basis, and class size is limited. Registration may be completed online at bendix.com; by phone at 1-800-AIR-BRAKE (1-800-247-2725), option 3; by email at [email protected]; or via fax (216-651-3261).

“Safety doesn’t happen just on the roads,” Hansen said. “At every turn, Bendix recognizes the increasing importance of wide-ranging technician training and education, and its role in creating safer highways for everyone.”