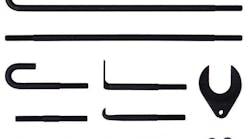

The Lock Technology Texas Twister, No. LT855, allows technicians to convert an air hammer into a pneumatic slide hammer. Its curved air bit snaps into the collet of the air hammer. Then technicians can reverse the air hammer handle in their hands and use their thumb to push the trigger, generating pulling power from the air hammer. The tool offers one-hand operation, and allows controlled part removal. The axle crow foot and pry bar sealer puller can be used to remove stubborn axles and inner axle seals, while the flat blade puller can be used for removing frozen distributors, pulley wheels and speed sensors without damaging them. The J-shaped hammer bit allows users to hammer from the back side, and the double-ended female 1/2-20 connector bar joins the Texas Twister to pullers. The 20" extender bar lengthens the tool.

The review

Any tool that helps save a technician’s time may be worth keeping around the shop. Eric Moore of DeMary Truck in Columbus, Ohio, appreciated that the Texas Twister made disassembly easier.

“Being able to use an efficient tool in the toolbox for tasks that would usually be labor intensive is almost a dream come true,” Moore says.

Moore used the Texas Twister for a variety of repairs, such as removing an axle on a UD 2600 that was sticking and removing the parking brake drum on a Mitsubishi Fuso FM series.

“One of our techs used the Texas Twister to remove an inner axle bearing and race,” Moore adds. “He said it was much easier than the slide hammer, and being able to use the leg adapter and slide it behind the race made it fairly painless, instead of cutting the race apart, which throws a lot of sparks and certainly isn’t as efficient.”

“Hands down, the best feature is the Texas Twister’s compatibility with standard slide hammer adapters and accessories,” Moore says. “We were able to use a hub adapter to pull an axle that was sticking.”

The Texas Twister came with all of the pieces laid out in a molded tray with a cloth bag. The setup involved assembling the proper adapters and extensions and screwing them together, Moore says. The tool inserts into any standard air hammer.

Moore notes that while there were no instructions in the package, it wasn’t hard to figure out how things worked.

Moore has used several styles of slide hammers in the past, and has even made his own a time or two, but found that the Texas Twister was able to make difficult disassembly easier.

“We only had a few instances where we [used] the Texas Twister,” Moore says. “The times we did, however, it was amazing just how well it works, and the ease with which is helps disassembly.”

While Moore may not have needed the Texas Twister to complete every job, he appreciated its time savings whenever he used it.

“[This is] absolutely a fantastic tool that I certainly believe we will continue to find new uses for,” Moore concludes.