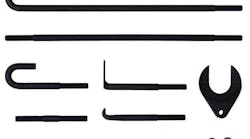

The Lock Technology Texas Twister, No. LT855, allows technicians to convert their air hammer into a pneumatic slide hammer. Its curved air bit snaps into the collet of the air hammer. Then techs can reverse the air hammer handle in their hands and use their thumb to push the trigger, generating pulling power from the air hammer. The tool offers one-hand operation, and allows controlled part removal. The axle crow foot and pry bar sealer puller can be used to remove stubborn axles and inner axle seals, while the flat blade puller can be used for removing frozen distributors, pulley wheels and speed sensors without damaging them. The J-shaped hammer bit allows users to hammer from the back side, and the double-ended female 1/2-20 connector bar joins the Texas Twister to pullers. The 20" extender bar lengthens the tool.

The Q&A

PTEN spoke with Ellery Casey, CEO, Lock Technology, to learn more about the Texas Twister:

PTEN: What are some of the most important or notable features and characteristics of the Texas Twister?

Casey: This tool converts an air hammer into a pneumatic slide hammer.

PTEN: How does it work?

Casey: The tool's user starts by inserting a 180-degree primary bent bit into a hammer. Then the user connects one of the kit's pulling/hammer bits, and then turns the air hammer around so his or her thumb is pushing on an air hammer trigger instead of pulling on a trigger. The air hammer is now a pneumatic puller.

PTEN: Why was the Texas Twister developed?

Casey: This tool was developed so automotive technicians could utilize an air hammer for parts-pulling applications.

PTEN: How does the Texas Twister help technicians save time and do their jobs with greater ease?

Casey: It allows for single-hand operation in parts removal applications, especially in tight, confined areas. This frees the technician's other hand for greater control. Employing the Texas Twister also allows a technician to utilize air-pulling power over manual, two-handed slide hammer operation.

PTEN: What types of jobs does the tool work well for?

The Texas Twister works well for the following jobs:

- Axle/seal

- Engine pulley

- Distributor

- Speed sensor

- Motor and transmission mount

- Suspension parts removal and installation

For more information, visit www.ltitools.com