Trailer whispering: Benefits of listening to smart trailers

If trailers could talk, wouldn’t that make the technician’s job a lot easier? Various systems could just tell you what’s wrong and what they need to get right again. Thanks to the advent of sensors and telematics, modern trailers really do talk. Smart components such as tire pressure monitoring systems (TPMS) and transport refrigeration units (TRUs) can now indicate to management and drivers anything from tire pressure to trailer temperature.

This lets fleets prevent losing a load of perishables due to a faulty condenser, or avoid a blowout by taking care of an underinflated tire.

“We’ve had certain customers give us feedback of a 70% reduction in roadside calls,” said Jonathan Gravell, EVP of Pressure Systems International, which makes TPMS devices and telematics software. “That’s huge. It really is a great opportunity to turn your fleet from being reactive to proactive.”

If one component can do that, then there’s no limit to the benefits a fleet could reap when every system on their trailer has been given a voice to articulate exactly what its current condition is. This enhanced communication, made more possible with telematics on the software side and improved gateways on the hardware end, makes the fleet more informed and more profitable, too.

Read more: Is it time for smart trailer adoption?

“When a fleet is looking at smart trailers as a way to save money, it’s about improving their operations,” said Cliff Creech, SVP at Phillips Connect, a trailer and chassis telematics provider. Because of the improved efficiency and health monitoring, and ability to dispatch the right resources when needed, Creech said, fleets using connected trailers “are able to operate and maintain their fleets at levels they just weren’t able to do before they invested in a smart trailer.”

The challenge now will be making sure each voice can be heard, and various data streams don’t drown each other out.

“There are over 60,000 diagnostic trouble codes that are registered [in SAE recommended practice J1939 alone],” said Jon White, transportation industry consultant. “With that volume of data that can come in, the poor guy that’s standing there in the shop trying to repair the piece of equipment and has got to look at diagnostic and repair codes has to have some support.”

Each fleet will have to integrate and prioritize based on their operational needs and budgets, but it’s important to know just what’s out there to help improve your trailer’s communication skills and how that can benefit your fleet. Here’s an overview of current solutions to help you do that.

TRUs

Temperature data was one of the earliest use cases for the Internet of Things in logistics. Now, it has evolved to provide actionable insights for reefers. Thermo King’s TracKing Pro Telematics offers an analytics dashboard that allows you to view emissions and receive predictive alerts. The Alarm Triage Insights feature recommends steps to understand and mitigate issues.

“[TracKing] provides energy usage analytics to help fleets understand what they can do to reduce fuel costs and track results from their actions,” said Dominic Hand, VP of IT and Connected Products, Thermo King. “It’s like having a technician riding in the trailer who is constantly checking to see what can be improved and making recommendations.”

Meanwhile, Carrier Transicold customers can leverage its Lynx Fleet telematics solution.

“From temperatures maintained in cargo areas to refrigeration equipment performance, Lynx Fleet monitors and collects scores of inputs from every asset,” said David Brondum, director of Telematics, Truck Trailer Americas, Carrier Transicold. “It distills, analyzes, and consolidates much of this mission-critical data into different insights so fleet managers can quickly spot assets that may require special attention.”

Fifth Wheel

Every tractor-trailer needs a fifth wheel, but Fontaine Fifth Wheel claims it’s the first to offer one with a brain. The SmartConnect fifth wheel provides fifth wheel telematics, locking status notifications, lock position sensors, and adjustment and wear updates, increasing service life and reducing maintenance costs.

“Basically, we’re taking the guesswork out of fifth wheel maintenance and automating it,” said Shane Wolfe, director of engineering, Fontaine Fifth Wheel. “It can accurately anticipate maintenance needs before problems surface.”

Jost International also offers ‘smart’ fifth wheels with the UBK Sensor Wheel and Loc-Light sensor system. The former offers in-cab notifications when the fifth wheel is safely coupled, while the Loc-Light uses indicator lights on the wheel itself.

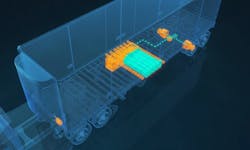

Gateways and GPS

Trailer gateways are the voice box of a trailer. While Phillips Connect’s EZTrac gateway offers GPS tracking, the company’s Smart7, StealthNet, and SolarNet gateways provide tracking and more. Often mounted on the trailer nose or door, the SolarNet comes with an integrated, solar-powered tracking system that covers trailer status and location, while the StealthNet features hidden installation and health, location, and efficiency data. The Smart7 gateway covers GPS location and tracking, light-out detection, and a PLC reader to handle ABS fault codes. To Cliff Creech, the features beyond GPS tracking are what truly make a ‘smart’ trailer.

“People who want [affordable] prices tend to start off looking at EZTrac,” Creech noted. “And when they look at what they’re really trying to accomplish, they buy a Smart7 or a StealthNet or SolarNet product instead.”

Lighting

Lighting telematics can notify drivers and fleets when their lamps short or burn out, which is critical when lights are one of the top five out-of-service violations of the Commercial Vehicle Safety Alliance’s 2023 International Roadcheck.

Grote Industries, a vehicle lighting manufacturer, offers the 4SEE Smart Trailer System, which uses a CAN-based harness and Smart Nosebox that can integrate rear-view cameras, ABS data, cargo sensing, and lamp monitoring. Smart Tail Lamps pull data directly from the trailer’s lights.

“If there are issues with a lamp, the driver and/or fleet team will receive a notification that the lamp is not operating,” Grote Industries’ CJ Biank reported. “The specific location of the lamp will be automatically identified for easy repair/replacement.”

Wheel-end sensors

P.S.I. offers both physical and digital versions of ThermALERT, which monitors wheel-end temperatures to avoid costly wheel-off events.

“Instead of a thermal event happening on the trailer, with a sensory input, we can now say, ‘Your trendline and your standard for this application is 125 degrees,’” Gravell explained. “Then you can start flagging anomalies.”

SKF, a bearing manufacturer and seal supplier, offers the TraX Wheel End Monitor, which tracks wheel bearing vibration and raceway spalling.

“While using TraX WEM, it alerted us to a bearing issue well before we could have found it and even before their PM cycle would have caught the issue,” said Kyle Mitchell, regional service manager at Maverick Transportation. “We were alerted well before there was a bearing failure or catastrophic event.”

TPMS and ATIS

TPMS and automatic tire inflation systems (ATIS) are some of the most common trailer integrations, said CJ Biank, global market manager – Networks Business at Grote Industries. Many systems offer alerts when tire pressures deviate from certain thresholds, such as Aperia’s Halo Connect, P.S.I.’s TireView, or ConMet’s SmartAir - TPMS. ATIS systems like SAF-Holland’s SAF Tire Pilot Plus and Drōv Technologies’ Drōv SI system offer automatic tire inflation via hubcap air hoses. Both systems let fleets actively manage their tires.

“As part of our [TaaS] managed care program, if we’re alerted about tire pressure issues from the sensing system, we dispatch a technician to repair the exact tire we indicate, so the customer avoids sending a driver to a trailer with an imminent failure,” said Cory O’Brien, VP of Marketplace Operations, Wabash. “This saves time and money for all parties involved.”

Cargo and axle sensors

Cargo cameras and sensors are not only helpful to deter thieves but also critical for meeting weight regulations. These systems can be as simple as tracking if a trailer is full or empty, or as complex as monitoring volumetric load data or door open and close sensors. ConMet’s SmartAir – Axle Load can monitor weight distribution across axles by tracking air suspension line pressure and provides alerts if load adjustments need to be made.

Roady Ready by Clarience Technologies’ FleetVIZ platform also offers load status and door sensors.

“Wabash makes the Road Ready smart trailer system standard on all dealer stock units as well as all TaaS units, and it’s a key enabler for Wabash to continually improve uptime and total cost of ownership,” O’Brien said. Wabash advises tracking “weight sensing for durability, safety and compliance, [and] door sensors for theft reduction.”