One of every four trucks put out of service during the last International Roadcheck was for brake system violations. During its three-day North American safety blitz this spring, the Commercial Vehicle Safety Alliance will again focus on brakes. Looking at recent out-of-service violations stats, here are some expert tips to help your vehicles earn a passing CVSA sticker.

"Considering that a high percentage of violations for brake issues are air leaks and chafed air hoses, a big part—but not all, of course—of these could be avoided with a good pre-trip inspection," Keith DiRuscia, manager of fleet maintenance at Pitt Ohio, told FleetOwner previously. "We still keep our preventive maintenance intervals at a point where we catch most brake thickness and cracked lining at the shop level."

See also: Roadcheck 2023 blitz to focus on ABS, cargo securement

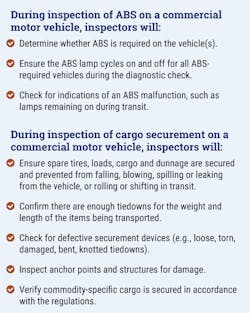

The focus on May 16-18 will be on anti-lock braking systems (ABS) and cargo securement—along with other out-of-service criteria.

While ABS problems don't lead to out-of-service violations, CVSA wanted to focus on the critical role ABS plays in reducing the risk of collisions by preventing the wheels from locking up or skidding, allowing a driver to maintain control of the vehicle while braking. Improper cargo securement risks drivers and other motorists by adversely affecting the vehicle's maneuverability or causing unsecured loads to fall, resulting in traffic hazards and vehicle collisions.

For 72 hours, CVSA-certified inspectors in the U.S., Canada, and Mexico will examine commercial vehicles and check up on drivers at weigh stations, inspection areas, and along roadways. Most vehicles and drivers will have a routine North American Standard Level I Inspection, where inspectors focus on driver and vehicle safety compliance.

- Vehicle safety: Inspectors will ensure the vehicle's brake systems, cargo securement, coupling devices, driveline/driveshaft components, driver's seat, fuel and exhaust systems, frames, lighting devices, steering mechanisms, suspensions, tires, wheels, rims, hubs, and windshield wipers are compliant with regulations. Inspections of motorcoaches, passenger vans, and other passenger-carrying vehicles also include emergency exits, seating, and electrical cables and systems in the engine and battery compartments.

- Driver safety: Inspectors will check the driver's operating credentials, hours-of-service documentation, status in the drug and alcohol clearinghouse, seat belt usage, and for alcohol and/or drug impairment.

During Roadcheck 2022, more than 12,000 vehicles and 4,000 drivers were put out of service during nearly 60,000 inspections in the three countries. The top vehicle violations last year were for brake systems, tires, defective service brakes, lights, and cargo securement. The most common driver violations were for false logs, driving with the wrong class license, hours of service, suspended license, and no medical card.

Vehicle out-of-service rates in the U.S., Canada, and Mexico were 23% in 2022, according to the CVSA. The out-of-service driver rate was 6.4%.

CVSA recently updated the 2023 North American Standard Out-of-Service (OOS) Criteria. The changes took effect on April 1.

The vehicles that pass Level I or V inspections are eligible for a CVSA decal, which can be affixed to the vehicle and is valid for up to three months. During the 2022 Roadcheck, inspectors distributed 14,200 decals showing future inspectors that the truck had recently passed. CMVs had a 77.2% passing rate, and 93.6% of drivers did not receive out-of-service violations.

Looking at the top violations of recent years, here are some tips and guides on how fleets and commercial drivers can prepare and keep driving through International Roadcheck 2023.

Brake systems

Seven of the top 20 CVSA violations in 2022 were brake related.

"If you stop and think about that, the mechanism that stops an 80,000-lb. truck is among the most noted violations," noted former Washington State Patrol officer Fred Fakkema, VP of safety and compliance at Zonar Systems. "That alone should encourage the driver to do a proper pre-trip inspection to get in that safety mindset before leaving the yard."

Fakkema noted that drivers are last on the line of defense from out-of-service violations. Problems such as pressure loss or an inoperable parking brake should be discovered during pre-trip inspections—not by a certified inspector.

"Once a fleet realizes they may have an issue with brake violations, it may be too late, and they will have already received numerous roadside inspections with brake violations," he said. "A fleet should always have pre-trip inspections and identify brake violations in their ongoing in-service training. The training and reinforcement of these issues are vital—not only for the safety of the driver but also for all motorists on the road."

Bendix Commercial Vehicle Systems, one of the top brake and safety system providers, offers tips on what fleets should check daily, weekly, and monthly within their braking systems:

Everyday brake checks

- Check for damaged or loose-hanging air chambers, pushrods, or slack adjusters.

- Make sure each axle's slack adjusters are extended to the same angle. Different angles can indicate an out-of-adjustment brake or a broken spring brake power spring.

- Examine tubing and hose condition, positioning, and connections.

Every week brake check

- Perform a 90- to 100-psi brake application with the wheels chocked and the parking brakes released, and listen for leaks.

- Check air disc brake rotors for cracks.

- Inspect drum brake linings for wear and cracks.

Every month brake checks

- Check for moisture in the air system to prevent contamination that leads to component deterioration and system leaks.

"Pre-, post-trip, and regular inspections can go a long way toward catching some obvious violations, including loose hoses or damaged components like air chambers or pushrods," Mark Holley, Bendix director of marketing and customer solutions, wheel-end, said before the CVSA Brake Safety Week last summer.

That blitz put 13% of vehicles out of service. You can read more about maintaining the latest heavy-duty truck braking systems in this past feature.

Cargo securement

This year's International Roadcheck also focuses on cargo securement, which put 10.6% of vehicles out-of-service during the 2022 safety blitz.

CVSA advises drivers to verify proper cargo securement and inspect tiedowns during pre-trip and post-trip inspections as well as periodically during a trip.

During an inspection of cargo securement on a commercial motor vehicle, inspectors will:

Ensure spare tires, loads, cargo, and dunnage are secured and prevented from falling, blowing, spilling, or leaking from the vehicle, or rolling or shifting in transit.

Confirm there are enough tiedowns for the weight and length of the transported items.

Check for defective securement devices (loose, torn, damaged, bent, knotted tiedowns).

Inspect anchor points and structures for damage.

Verify that commodity-specific cargo is secured in accordance with the regulations.

Tires, wheels, rims, and hubs

Tire infractions were the second most common out-of-service violations during the last International Roadcheck. More than 3,300 vehicles were tagged for tire problems, making up 18.5% of all vehicle violations over the three days.

According to CVSA, where the rubber hits the road, inspectors will check tires for low inflation, cuts and bulges, regrooved tires on the steering axle, tread wear, and major tread groove depth. They will also inspect sidewalls for improper repairs, exposed fabric or cord, contact with any part of the vehicle, and tire markings, excluding it from use on a steering axle.

Beyond the rubber, inspectors will look at wheels and rims for cracks, unseated locking rings, and broken or missing lugs, studs, or clamps. That also entails checking rims for cracks or bends, loose or damaged lug nuts, elongated stud holes, cracks across spokes or in the web area, and evidence of slippage in the clamp areas.

Inspectors will also check the hubs for lubricant leaks, missing caps or plugs, misalignment or improper positioning, and damaged, worn, or missing parts.

Loose items on trucks, low air in the tires, or balding treads are warning signals to troopers that a driver didn't perform a pre-trip inspection of the vehicle, according to Zonar's Fakkema. "It's a serious situation if they don't do a pre-trip and you see lug nuts missing or not tightened so that a vehicle could lose a tire," he said. "Now you're getting into the accident threshold where it's going to cause a collision—and lawsuits are going to follow, especially if a tire comes off. Then it just expands from there."

He said that an initial pre-trip is one of the most important things a driver can do. "While they do it, it also puts them in a safety mindset. They're thinking about safety before leaving the yard. They're making sure their equipment is safe, and that thought process continues with them in the cab."

Lights

As recently as 2020, lighting was the most common vehicle violation for roadside inspections. During the 2022 International Roadcheck, lights made up 12.2% of all out-of-service violations. Light problems took more than 2,200 commercial vehicles out of service over the three days.

Checking all the lights on a Class 8 tractor attached to a 53-ft. trailer can take time. A driver who wants to check that all the turn signals are working, for example, has to turn one on, walk to the back of the trailer and check that it's flashing. Then, the driver has to go back into the cab, turn on the other turn signal, and walk around to check it at the rear of the trailer.

"Let's be honest. Does every driver do that?" Gino Fontana, a VP of operations for Transervice, asked rhetorically. "A lot of drivers will pop the hazards on, assuming that if the hazards are making everything blink, then the left and right signals work."

Transervice uses a trailer tester to troubleshoot lighting, air brake, and ABS systems problems quickly. "You hook it up to a trailer, and it takes you through a sequence," Fontana explained. "You can stand there, and it gives you five seconds of the left signal, five seconds of the right signal, five seconds of the brake lights, five seconds of the running lights, and pops the ABS light. We use technology to simulate what's going to happen when a driver is on the road to make sure all the lights are working before the truck leaves."

This article was originally published on FleetOwner.com.