Nearly seven years after floating the initial proposal, the National Highway Traffic Safety Administration on Thursday posted a final rule that updates two Federal Motor Vehicle Safety Standards for rear underride guards, increasing the performance requirements to a level that nearly all existing U.S. trailers already meet.

Specifically, the rule upgrades FMVSS No. 223, “Rear impact guards,” and FMVSS No. 224, “Rear impact protection,” which together provide protection for occupants of passenger vehicles in crashes into the rear of trailers and semitrailers.

“NHTSA’s priority is the safety of everyone on our roads,” said NHTSA Administrator Steven Cliff, “This new rule will improve protection for passengers and drivers of passenger vehicles while also meeting a critical mandate from Congress under the Bipartisan Infrastructure Law.”

For highway safety groups, however, the new standards are too little, too late. The result of the rulemaking process, which was initiated in 2015, is “completely inadequate” and will make road users “less safe,” Advocates for Highway and Auto Safety argued in a statement.

Indeed, the new rule is “substantially weaker” than the current test the Insurance Institute for Highway Safety has been using to rate rear underride guards for the last five years, noted Advocates President Cathy Chase—especially since nine major trailer manufacturers already meet it.

“Unfortunately, today’s action allows trucking companies to choose a less safe course of action at the expense of road user safety,” Chase said. “With large truck fatalities on the rise, the agency responsible for the safety of our nation’s roads needs to be taking action to improve, not imperil, protections for road users.”

Joan Claybrook, who served as NHTSA administrator in the Carter administration, characterized the new standards as “nothing less than regulatory malpractice.”

“It would have been better if NHTSA had not acted at all,” Claybrook said. “Instead of improving protections to reduce underride fatalities and injuries, the agency has gone backward by issuing a rule that 94 percent of trailers already meet.”

The organization has long urged the adoption of comprehensive underride guard safety standards.

But the NHTSA filing explained that additional modifications to the standards, to account for higher impact speeds and a wider range of impact overlap, come with performance tradeoffs and great cost, as well as being impractical for certain trailer types and applications.

In the works

Still, in announcing the new rule, NHTSA reported the agency also is implementing other underride provisions of the Biden Administration’s Bipartisan Infrastructure Law, including:

- Establishing a Federal advisory committee on underride protection, which will complete research on side underride guards for trailers and semi-trailers to assess their effectiveness, feasibility, benefits, costs, and impact on intermodal operations.

- Planning to publish an advance notice of proposed rulemaking to consider requirements for side underride guards for crashes into the sides of trailers and semi-trailers. This rulemaking also responds to a provision in the Bipartisan Infrastructure Law to report the findings of research on side underride guards in a Federal Register notice to seek public comment.

- Improving data collection of underride crashes by recommending inclusion of underride data in State crash data systems and by providing educational materials to State and local police departments on identifying and recording underride crashes; and

- Conducting research on rear impact guard designs that better protect occupants of passenger vehicles in even more rear underride crash scenarios.

The rule

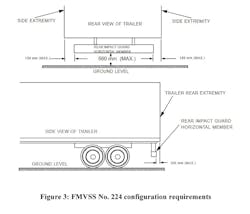

FMVSS No. 223, an equipment standard, specifies strength and energy absorption requirements in quasi-static force tests of rear impact guards sold for installation on new trailers and semitrailers. FMVSS No. 224, a vehicle standard, requires new trailers and semitrailers with a GVWR of 10,000 lbs. or more to be equipped with a rear impact guard meeting FMVSS No. 223.The standards, dating to 1996, are designed to ensure a rear impact guard is configured low and wide to impede a striking passenger vehicle, is strong enough to withstand a 35-mph impact—up from the current 30 mph—and has energy-absorbing capability to further mitigate harm to the passenger vehicle’s occupants.

The increase to 35 mph aligns the safety standards with another FMVSS, No. 208, “Occupant crash protection,” and with Canada’s rear impact guard standard.

The final rule is based on the “best available science,” the filing states.

In the cost-benefit analysis, which considers that 94 percent of applicable trailers already have CMVSS compliant guards, NHTSA calculates that equipment costs, plus a fuel-use increase for the added weight, results in a total incremental cost for U.S. fleets that ranges from $6.54 million to $7.69 million, depending on the rate of inflation.

The agency estimates that about 0.56 lives and 3.5 serious injuries would be saved annually by requiring all trailers to be equipped with compliant guards.

This article originally appeared on FleetOwner.com.