Roadside inspections can be a necessary evil for carriers and drivers alike. While they are designed to remove unsafe tractor-trailers from the roadways, these inspections can be a time suck for commercial drivers who are already in constant competition with their hours-of-service clock.

No matter how roadside inspections are viewed, the reality is that an inspection gone wrong is a mark against trucking companies and drivers.

The Federal Motor Carrier Safety Administration’s Inspection Selection System (ISS) is a guide for safety inspectors in selecting commercial motor vehicles for inspection. ISS scores are based on carriers’ safety performance data in areas of crash history, inspection history, driver history, and safety management experience. Law enforcement officers use ISS values to determine whether they will inspect certain vehicles over others.

ISS values fall under three categories: inspect (inspection warranted) for carrier scores falling between 75 and 100; optional (may be worth a look) for scores between 50 and 74; and pass (no inspection required) for carriers showing an ISS value between one and 49.

“A lot of drivers I talk to say inspections are just random. Most of the time, they’re not,” explained Mike Yonka, director of safety services for transportation at Sentry Insurance.Yonka started his career as a truck driver and has hauled everything from dairy, beef, poultry, fuel grade tankers, and auto parts from Mexico up to Canada. He’s no stranger to roadside inspections, and since his days as a driver, Yonka has worked his way up the ranks to fleet safety director and human resources director. Now, in his role at Sentry Insurance, Yonka helps fleets implement safety and training programs.

“Some carriers out there just don’t share that ISS information with their drivers,” Yonka said. “Drivers don’t understand that every time you are getting inspected or there’s a violation depending on what category it is, it drives up your score."

“If you explain to a driver that if you’re going through a weigh station and you have an ISS score of 85, and you’re in the red, and someone else is going through with an ISS score of 30, they are probably going to pick you,” he continued. “It’s not so random. And inspectors already know by looking at the profile of the carrier that they have an issue with inspections and vehicle maintenance.”

During his time as a fleet safety director, Yonka made it a point to share out-of-service violation numbers and ISS scores with everyone in the corporation. That, he added, goes a long way in helping drivers understand why they have been flagged and are being inspected at a higher frequency than others might be.

To avoid a red-flag event from safety inspectors, trucks, trailers, and drivers must be prepared before they even hit the road. That’s where proper preventive maintenance (PM) and quality pre- and post-trip inspections come into play.

Proper PMs

For long-time trucking industry veteran Kevin Pfost, technical service coordinator for Bendix Commercial Vehicle Systems, if fleets are conducting the right PMs regularly, they should never have a problem during a roadside inspection.

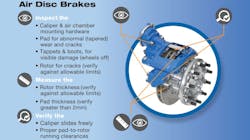

For technicians, proper PMs include measuring strokes on drum brakes and making sure slack adjusters are all positioned at the same angle. Drivers can check that out, too, during their pre- and post-trip walkarounds, Pfost noted.

That will be especially important this year from May 17 through 19 as the Commercial Vehicle Safety Alliance’s (CVSA) 2022 International Roadcheck safety blitz will focus on wheel ends.

“I do a lot of training for drum brakes, disc brakes, and a lot of fieldwork for Bendix, and every year, it’s the same thing,” Pfost said. “We are looking at a 20% to 25% failure rate in wheel ends.”The results of Roadcheck in 2021, for instance, show that brake systems took the top spot for violations in North America, accounting for 26.5% of all driver out-of-service conditions. Brake adjustments was the fourth highest violation in 2021, totaling 12.4% of overall violations.

According to CVSA, violations involving wheel-end components historically account for about one-quarter of the vehicle out-of-service violations discovered during Roadcheck. Furthermore, past data from the annual inspection blitz routinely identified wheel-end components as a Top 10 vehicle violation.

“What I find with fleets a lot is that the brakes don’t get measured,” Pfost said. “They look at them, a technician will grease them, but they don’t really measure the strokes. When you get pulled over in a roadside inspection, one of the very first things inspectors do is they measure your brake strokes at 90 to 100 psi of application pressure.”When law enforcement is looking at wheel-end components, they're actually doing a Level I inspection, meaning they're crawling underneath the cab and looking at the slack adjusters as well as the inside of the brake drums.

Underneath the truck, the DOT inspector marks the pushrod where it exits out of the bottom of the chamber, and then has the driver pump air down in the tanks until it’s between 90 and 100 psi, Pfost added. The inspector then applies the full brake and measures from the base of the chamber to that mark made on the pushrod. Chamber type and size tell inspectors at what distance that brake can extend and still be within the DOT brake limits, Pfost advised.

“Every year we are at 20% violations for brakes,” Pfost pointed out. “When the DOT inspector writes that ticket, he just has to give a causal problem. So, if the brake measures out of stroke, the inspector will call it the slack adjuster. It could be something totally different in the mechanism some other place, but all he has to do is write 'brakes out of adjustment spec.'”

Pfost reiterated that these issues can all be avoided during daily driver pre- and post-trip inspections and bringing in the truck for repair right away before it’s hooked and rolling down the road with a trailer full of freight.Pre- and post-trips

In collaboration with regular PM schedules, a secure trip on the road comes back to thorough, quality pre- and post-trip inspections from drivers.

“By conducting pre-trip inspections, drivers can catch the ‘low-hanging fruit’ law enforcement officers look out for on the road, such as turn signal lights, having a fire extinguisher—those are the things you should be checking in your pre-trip,” Fred Fakkema, VP of safety and compliance at Zonar Systems, told FleetOwner. “We always tell our customers that if you don't take care of your vehicle, you're going to get inspected a lot. It’s all part of the safety mindset. If the driver is in that mindset of always being safe, they're looking at their equipment and doing the right thing.”

Fakkema, a former state patrol officer for over 25 years and a graduate of the FBI National Academy, recalled his time as a state trooper and said that the biggest common denominator for mistakes on the road is complacency.

“It's really easy to get complacent,” Fakkema urged. “I always tie it into my law enforcement days when you see people have an ‘Oh no’ moment because they weren't really paying attention. And it's the same concept when driving a truck: You get comfortable. And once you're comfortable, you get a little complacent and then that's when mistakes can happen. That’s when you overlook something.”

Bendix’s Pfost explained that during pre-trip inspections, drivers also should check for air-line chafing and ensure that brake chambers aren’t rusted or have internal parts poking out. They should also check that the slack adjuster isn’t disconnected from the pushrod.

When it’s safe to do so, Pfost recommends drivers get under the truck to see what’s going on because that’s what enforcement officers will do during roadside inspections.

“Ultimately, it’s up to the driver to walk around the truck, listen for air leaks, and look underneath the truck with a flashlight,” Pfost advised.

Keeping a tidy cab also goes a long way.

“When inspectors walk up to the door and chat with the driver, they look at the truck’s interior,” Pfost said. “In their brain, if the driver doesn’t do good maintenance inside the cab, he isn’t going to do good maintenance outside of the cab. I had an inspector tell me one time that it was one of his keys right off the bat that let him know how far he’ll go in the inspection.”

As a former driver, Sentry’s Yonka feels most comfortable interacting with drivers at truck stops and over the road when possible. Often, after drivers drop a trailer, Yonka sees them get in their trucks and go without doing an inspection. That’s a mistake. During the trip, a tire could’ve gone flat, or lights might have stopped working.

Yonka uses his practical knowledge and over-the-road experience when talking to drivers. For instance, he’ll often ask truckers if they know the definition of flat tire. CVSA says anything 10 lb. of pressure less than what it’s rated at is flat and should be taken off, Yonka explained. But all too often, drivers don’t understand that.“One of the issues I bring up with carriers all the time is just because they have a CDL doesn’t mean they necessarily know the inspection process very well,” he advised. “That’s why we do training.”

Aside from making sure the truck can stop safely by looking at brakes to see if any seals are leaking or whether there is oil or grease on the brake linings, Yonka said drivers should also pay attention to that low-hanging fruit Fakkema had mentioned.

That means double-checking for emergency equipment, like triangles, and making sure fire extinguishers are fully charged and hanging up properly.

“My comment to drivers is whenever you are driving, you have to think of it as your family in that car in front of you,” Yonka urged. “Do you want to have bad brakes if that’s your family in front of you? Do you want to have anything wrong with your truck or be tailgating or speeding if that’s your family you’re following? You always have to think about that because it is somebody’s family.”

Having proper documentation is also an important part of the inspection process, Yonka pointed out. Drivers should be able to show law enforcement officers the steps that they followed during their pre-trip inspections.

“If there is a severe accident and you are going into court, they are going to ask from an insurance perspective what you did,” Yonka said. “Do you have a process? Did you follow a certain way of handling those inspections? Did you do your pre-tip inspection and make sure everything was good before you hit the road?”

Yonka often urges carriers to train drivers on their processes, as high out-of-service violations and ISS scores can impact insurance premiums. And when drivers find a better way to conduct their inspections, Yonka advised carriers to take note and always listen to driver feedback.

Editor's note: This is the first in a two-part series on roadside inspections. Part 2 focuses on advancements in e-inspections.

This article originally appeared on FleetOwner.com.