Over the last five years, the industry has seen a 50 percent increase in the spec'ing of active braking systems on Class 8 vehicles.

With safety a continually discussed topic across the commercial vehicle industry, groups are working to continue the push for wider visibility and acceptance of advanced driver assistance systems (ADAS) on heavy duty vehicles.

“Our customers tell us that safety really has replaced fuel economy as their number one priority when it comes to making purchasing decisions,” said Len Copeland, product marketing manager for Detroit Products, during a recent discussion on current and future considerations of ADAS technology for heavy duty trucks. Copeland was one of four industry experts who shared insights during the S.5 study group session at the Technology & Maintenance Council Spring Meeting.

Where vehicle technology ranks

The American Transportation Research Institute (ATRI) conducts an annual top industry issues report for both fleets and drivers to understand top industry challenges.

While vehicle technology isn’t directly stated as a top issue on either list, Dan Murray, senior vice president of the American Transportation Research Institute (ATRI), indicated there are “hints” of ADAS technology impacting both driver and carrier concerns.

In the ATRI 2020 top industry issues results for drivers, automated truck technology came in as the number-six issue. On the same survey conducted for carriers, Murray indicated ADAS and other safety technologies can help to address concerns such as rising insurance costs.“Insurance costs do not impact the industry equally,” Murray said. “When you look at insurance costs per mile by fleet size, you see the smallest carriers – who oftentimes have the hardest time finding the capital to invest in technology – are most dramatically impacted by these insurance costs, particularly recently, with these double-digit increases.”

Murray did indicate there is a misconception, however, that insurance companies will offer lower up-front premium discounts to fleets who spec advanced safety technologies. The reality is a bit more nuanced, suggesting ADAS usage can help to improve fleet safety overall, thereby lowering insurance premiums in the long-run.

“Commercial insurance does not give front-end discounts for technology adoption,” Murray said. “The business model for commercial insurance says, ‘You invest in these systems, and your loss history, your experience, ratings, all these other actuarial terms will ultimately benefit you through fewer crashes and lower costs.'”

Overall, he anticipates vehicle technology will play a more prominent role on the ATRI top industry issues list in the not-so-distant future. “I wouldn't be surprised next October when we release the [20]21 report that we will see technology much more overtly in these lists.”

As it relates to operational costs of trucking, Murray indicated ADAS can potentially both help and hurt fleet operations. ATRI conducts an annual operational cost analysis, and this report indicates a continued trend of increasing operational costs – from a maintenance and repair standpoint to insurance premiums. “We're buying newer and newer trucks and trailers but we're not seeing decreases in repair and maintenance costs,” Murray advised.

“The question legitimately comes into play, ‘How and where can I fit ADAS into my investment plans, my adoption plans?’” he added.

Perceived barriers to adoption

The Federal Motor Carrier Safety Administration (FMCSA) Tech-Celerate Now program is a joint effort between numerous industry groups, including the American Trucking Associations (ATA), the ATA Technology & Maintenance Council (TMC), ATRI, and Owner-Operator Independent Drivers Association (OOIDA) Foundation. The Tech-Celerate Now program looks to research and educate the commercial vehicle industry on ADAS development, implementation, and impact.

Ross Froat, director of technology and engineering policy for ATA, shared progress on current achievements of the program since its launch in January of 2020. The program conducted three industry stakeholder surveys with a collection of 1,000 responses to understand industry perspective on ADAS, as well as the development of two ADAS research reports highlighting ADAS baseline adoption and research on technical and market barriers of adoption with ADAS. Additionally, a safety guide and investment guide have been developed to help educate industry stakeholders on ADAS adoption. All research and materials have been made available for the industry.

The Tech-Celerate Now program conducted an ADAS survey with participation from 30 industry companies serving the ADAS segment – including truck manufacturers, component suppliers, and aftermarket suppliers – to understand market penetration and availability of ADAS technologies. The survey explored ADAS technology available on Class 3 through 8 vehicles in 2019 through 2021 model years. Results found an estimated 130 vehicle models available. Of those 130 models, Class 8 trucks make up the largest percentage of vehicles at around 39 percent; followed by Class 7 sharing 18 percent of makes available.Details from research conducted through the Tech-Celerate Now program indicate that current implementation of ADAS technology on Class 8 trucks exceeds those of other vehicle classes. While availability of the technology is accelerating, the acceptance of technology usage is another story. For instance, of the truck manufacturers, 100 percent of Class 8 trucks built between 2019 through 2021 have the option to spec automatic emergency braking (AEB), air disc brakes, and adaptive cruise control. That doesn’t mean, however, that all fleets opt to include these systems on their vehicles, said Froat.

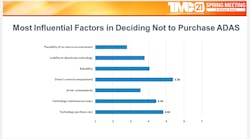

As it relates to ADAS adoption plans, the recent survey helped to understand barriers to adoption. Of the most influential factors in deciding not to purchase ADAS, ATRI’s Murray pointed out, both driver and carrier respondents indicated driver control being comprised was the number-one concern.

“We have a lot of work cut out for us in the Tech-Celerate Now program, educating, increasing awareness, but most importantly conveying accurate real-world information to offset a lot of these misunderstandings and concerns,” Murray said.

When it comes to perceived challenges impacting the adoption of ADAS, top ranked issues for both drivers and carriers included technology purchase costs, cost of insurance premiums, and driver acceptance.

“We have to educate motor carriers on driver acceptance, and to do that we've got to educate drivers on the benefits,” Murray said. “Motor carriers are astutely aware that driver acceptance is going to make or break this adoption program very, very quickly.”

Current and future ADAS developments

While improved safety is certainly a driver for the continued advancements in ADAS, Detroit Products' Copeland suggested fuel economy and vertical integration are also enablers of ADAS development.

For instance, AEB technology requires a number of vehicle systems to work in concert seamlessly with one another to work most effectively.

“Systems that are designed and tested to work together are highly efficient and reliable," Copeland said. "What I'm proposing here is that the push towards vertical integration really accelerated the proliferation and availability to ADAS that were proprietary.”

The industry now has various ADAS options available as standard offerings on heavy duty vehicles today, such as active emergency braking, adaptive cruise control, and lane keep assist. Copeland noted the industry continues to see a shift from warning systems to active systems which will engage braking or steering systems if the driver does not intervene. This can be attributed to the integration of various detection systems on the vehicle working together to monitor the vehicle’s surroundings.

“Combining the camera and the radar, what that does is it increases the confidence of object recognition that it allows the system to have confidence in the targets – in identifying pedestrians, identifying moving objects that come to a stop, identifying lane markers, identifying road signs, et cetera,” Copeland said.

Copeland acknowledged driver reluctance of adoption can stem from concerns of more alerts and notifications in the cab. As companies continue to develop these technologies, it is important to keep this in mind. “It's a focus by – I think – all OEMs to reduce the fatigue, keep the drivers more comfortable, [and] have less buzzers, in addition to keeping them safer,” Copeland said regarding ADAS technology development.

Copeland advised a number of new technologies on the horizon to watch, including:

- Mirror cameras: These systems could either replace or complement existing mirrors. They are designed to increase the field of view around the vehicle, particularly during turns and slow maneuvers. Mirror cameras can also provide vision stability when backing the tractor trailer into a loading dock. Other benefits include increased visibility during inclement weather compared to physical mirrors, decreased aerodynamic drag, and the ability to record video.

- Environment cameras: These cameras provide a bird’s eye view around the truck, providing better visibility of small vehicles, pedestrians, and various objects. They can monitor traffic, and also act as a theft deterrent, Copeland noted.

- Blind spot warning with braking: While the blind spot warning systems are already available, Copeland noted braking functionality is a not-too-distant feature.

- Cross traffic accident mitigation: This system utilizes side radar with cameras to assess the velocity, size, and behavior of vehicles. It would also have traffic sign recognition to know whether or not the truck needs to yield right of way.

One fleet’s experience

Maverick Transportation has been at the forefront of testing various advanced safety technologies, working with various vehicle suppliers and manufacturers to outfit assets with ADAS technology. According to Maverick Regional Service Manager Greg Johnsen, the fleet started testing and spec'ing various safety technologies in 2001, with the adoption of automatic tire inflation systems on its trailers. Since that time, Johnsen confirmed the company has implemented collision warning and transitioned to collision mitigation systems, forward facing camera monitoring technology, active steering, and more. Most recently, Maverick outfitted several trucks with cameras to replace mirrors and is awaiting the arrival of several units outfitted with rear outside-facing cameras.

“Maverick is going to look at anything that we can assist our drivers in being safer, or making their job easier, so we're going to continue to look at things going forward,” Johnsen noted. He stressed, however, the importance of thinking beyond just the driver when widely adopting ADAS technology.

“We can put all the technology that we want into our units; if we don't have a trained staff to troubleshoot, repair, or replace and understand why we're doing that, then it's money that we're never going to get a return on,” Johnsen said.

When Maverick decides to test a new safety technology, they will first create a test group and add that technology to a few select units. Then, Maverick gathers feedback from drivers on the usage of that technology on the truck.

“During that time, of course, the manufacturer of that product will come in,” Johnsen said. “And we will have discussions on troubleshooting guides, weak points that they may have noticed [with] other fleets that have tested this, what they have done to address those [weak points] so we know when we have a similar issue where to start looking, [et cetera].”

After gathering that information, Johnsen advised the team will set up hands-on training for technicians with these suppliers. After training is completed, Maverick creates in-house standard operating procedures (SOPs) utilizing the manufacturer’s recommendations and adjusting guidelines for the specs of units run by Maverick.

One challenge Johnsen confirmed was the instances of outside service providers servicing Maverick vehicles. To plan for this, the fleet will work to educate these service providers with the necessary information Maverick has on-hand at its own in-house service locations.

“As we get trucks in dedicated locations, we will have our internal [technicians] drop to our preferred service providers and pass that training and SOP-specific [information] for our equipment onto them to assist them with getting our trucks up and running,” Johnsen said.

As it relates to future ADAS testing plans, Johnsen confirmed the fleet is looking at 360-degree visibility environment cameras to monitor tractor-trailer surroundings.