While tires, brakes, and lighting continue to cause the most safety inspection headaches for fleets, there are some other areas to not lose sight of.

Chuck Pagesy, director of safety for Penske Transportation Solutions, reviews all of the CSA violations that come through Penske’s operations. One that is somewhat frequent, but completely preventable, is no proof of annual inspection. Perhaps the sticker had fallen off or was defaced. Sometimes a trailer simply didn’t get its annual inspection.

A similar example is a missing, discharged, or improperly secured fire extinguisher.

“Again, this is something very easy to catch during the pre-trip inspection,” Pagesy points out. “Another one is missing or damaged reflective triangles.”

Cargo securement actually ranks high on the list of inspection failures. The U.S. and Canada Commercial Vehicle Safety Alliance (CVSA) International Roadcheck, conducted June 4-6 of 2019, resulted in more than 9,500 vehicles being placed out of service. Roughly 12 percent were tied to cargo securement violations.

“One of the most common mistakes is not having enough tiedowns to prevent movement in all directions,” says Ralph Abato, president and managing director of Doleco USA, a provider of lifting and securement solutions. “Another major mistake is that tiedowns are not tightened enough because operators have not periodically re-tensioned them.”

To avoid these and other cargo-related issues, Abato says fleets should fully familiarize themselves with Federal Motor Carrier Safety Administration (FMCSA) Regulations, Parts 392 and 393. Additionally, the following items should be part of a thorough pre- or post-trip inspection checklist:

- Check for sharp edges and use edge protection when necessary

- Go by the WLL (working load limit) formula as dictated by the FMCSA when selecting tie-down straps, chains, or other securement devices

- Inspect all anchor points for soundness

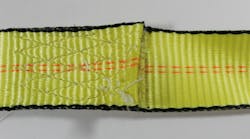

- Inspect tie-down devices for defects

Suspensions also require special attention. They account for roughly 4 percent of the CVSA out of service violations.

“Most of the time, the inspector will see a problem or notice an issue with parts,” says Chuck Boden, technical support specialist for Link Manufacturing, a manufacturer of suspension systems and lift axles. “Both steel spring and air spring failures are things that will be easily noticed on a roadside inspection.”

For steel spring suspensions, Boden says cracks in hangers is the most common failure. For air spring suspensions, it is an air spring failure or control valve failure. In some cases, the inspector will hear air leaking or feel the air leaking.

“In most cases, a good pre-trip inspection should have noticed the problem and written it up,” Boden says. “Some problems might be harder for the driver to find, but a good preventive maintenance schedule should identify the problem. While many of today’s suspensions have connections that do not require grease, they do need to be inspected on a regular basis.”

Frames also made the top 10 list, accounting for 1 percent of inspection violations.

“An inspector will be looking at the frame for rust, corrosion, cracks, buckles, loose and missing bolts, flange damage, bent cross members, and sagging,” says Howard Williams, corporate technical sales specialist, Bee Line Co., a manufacturer of wheel alignment, computer balancing, and collision correction equipment.

According to Williams, fleets should educate drivers and technicians about what to inspect to avoid violations and warnings. “Please reference state and federal compliance manuals for guidelines to re-enforce preventive maintenance inspection routines,” Williams says.

As an extension to lighting, which is the number-five cause of inspection violations, overall electrical system issues can also cause problems.

“One of the most important electrical components of a truck or trailer is the J560 7-way cord that connects the two electrically,” says Larry Rambeaux, sales application engineer for Purkeys, a battery solutions provider for heavy duty fleets. “Fleets should make sure they are only running the green-colored 7-way cords. The color denotes they are designed for modern ABS-equipped trailers. Fleets should also invest in the equipment and training to actually test these 7-way cords.”

According to Rambeaux, a good 7-way cord can mean all the difference when it comes to fully functional lighting systems. “The LED lights used on today’s trucks will only operate down to a certain voltage, and the voltage is very cut and dry,” Rambeaux explains. “With old incandescent lamps, they just get dimmer and dimmer if the voltage decays. But with LEDs, they go from working to nothing when they hit the low-voltage limit.”

Another electrical system issue Rambeaux has observed relates to the amount of corrosion often found on the tractor 7-way socket. “The end that goes to the trailer is connected and disconnected many times,” he says. “But the tractor end often hasn’t been touched since the truck was built. We have seen corrosion so bad that it took using two 2x4s prying on the back of the cab to get the plug to come out.”

In other words, fleets should make this part of a regular inspection and preventive maintenance routine. Doing so will only reduce the chances of drivers landing in hot water when their trucks are in the inspection station.