Recent stats point to root causes for technician turnover

There are plenty of studies out there that posit an employee’s productivity output is directly related to their happiness and how engaged they are. For example, an oft-cited 2019 Oxford University study found happiness could improve productivity by 13%. The researchers studied call center workers, so if this relationship is also true for vehicle repair technicians is anybody’s guess. But an I-CAR study marked technician turnover at 30-40%, so many aren’t happy with where they’re at.

A 2024 survey of collision techs I-CAR put together in conjunction with the Society of Collision Repair Specialists (SCRS), and Ducker Carlisle pointed to bad culture and feelings of being undervalued as the top reason they left their current job (19%). Better compensation (16%) and work-life balance (15%) followed.

WrenchWay’s most recent auto and diesel employment statistics, gathered from the company’s Voice of Technician Survey and WrenchWay Shop Talk polls, also revealed that technician job satisfaction is not as strong as it could be in the industry. In fact, a few survey results scream out that there are more disgruntled techs than satisfied ones.

- 21% of technicians would recommend the industry to a friend

- 88% of technicians have considered leaving the industry

- 75% of respondents said that the public perception of technician careers is not improving

That first stat breaks down to only one out of five technicians recommending the industry. This job, by the way, doesn’t require a degree, has high demand for the foreseeable future, and great earning potential. So what’s the deal?

Reasons for disillusionment

Our editor-in-chief wanted to find out if there was merit to the stat that only about 20% of techs would recommend the trade and asked techs on LinkedIn to chime in.

He received several responses from auto and diesel professionals that point to pay and general burnout as driving factors for less-than-enthusiastic feelings about the industry.

“The bottom line is, I don’t hate what I do, but there are better ways to make a living,” said Brandon Harmatiuk, sr. master technician at Subaru. “The amount of effort it takes to become an elite technician applied to a different career could probably get you more freedom and better comp. If I had put the energy that I have put into this into, say, business ownership, real estate, or creative production, I truly think I could be work-optional at this point in my life.

“Instead, I’m looking at 20 more years of this.”

According to Sean Wilkin, an emergency field service technician for Cox Automotive Mobility Fleet Services, many don’t even get that far.

“The number of people that I’ve seen come into this industry and get burned out and leave after a couple of years is concerning,” Wilkin commented. “The job can be hard for everyone—and it is hard for a new tech. We shouldn’t have a tech shortage, but as an industry we let people walk away.”

Repairing trucks 50 to 60 hours a week for several decades isn’t for everyone, so there’s bound to be some attrition. But Wilkin and others believe there are other factors leaders can control to keep more techs in their shop—and industry overall.

Flat rate’s downward slide

One area to consider is the issue of flat rate. One in five techs prefer this structure (though not necessarily the same who would not recommend the industry). Meanwhile, 37% would like hourly plus a production bonus.

“The majority hate it,” said Mark Wilson, co-founder and CEO of WrenchWay in a 2023 webinar on addressing technician frustrations. “And I think they hate parts of it more than I think they hate all of it because traditionally, I think shops have used [flat-rate pay] to take advantage of technicians.”

James Cubberly, who started in the 1990s as a fleet maintenance tech and spent 17 years as a diesel engine test tech and warranty administrator for Navistar, advocates for ditching flat rate and incentivizing with productivity bonuses.

"Flat rate is why I left being a line tech," Cubberly wrote.

He noted the experience he accrued allowed him to move on to other roles not dependent on grinding out more billable hours.: "I love the industry and used my tech experience to find employment in auto/machine corporate customer service roles."

Cubberly went on to become a diesel instructor for Universal Technical Institute and now does warranty admin for CNH Industrial.

The I-CAR survey found shops using a flat-rate system were less likely to recommend the collision repair sector, given a value of -25. Techs in shops using team-based compensation were far more likely to recommend the career, with a value of +40.

Work-life balance

Perhaps some of the animosity towards flat-rate pay is that you take a pay cut anytime you miss work. That means you miss out on important family events and come in even when your body says you shouldn’t.

According to WrenchWay’s findings, 57% of technician respondents reported that they were satisfied with their current work-life balance. One way to improve this is offering more flexibility: 86% said that it is “important or very important” for shops to offer flexible scheduling.

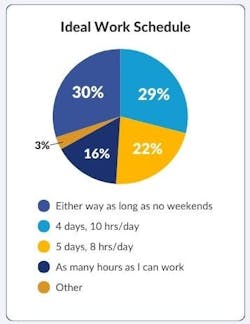

Could four-day work weeks with 10-hour days be the solution? According to WrenchWay data, 30% of technicians preferred a shorter work week with longer hours. But an equal amount didn’t care if they worked a four- or five-day week, as long as they didn’t have to work weekends.

According to Peterbilt mobile technician Celine Young, getting that four-day workweek is not worth working on the weekend.

“I had three days off, but when stuff happened on a Saturday, I had to leave early because I had to get to bed by 7:45 p.m. to be up at 4 a.m. to get to [the shop] at 5:30 a.m.,” Young said. “You really didn’t have a weekend to be able to go to birthday parties and go to family events.”

Communication

With so many different voices preferring different models, shops should conduct their own internal research to see what will work best without breaking efficiency and productivity in the process.

Communication is a two-way street, and techs also want feedback from management. WrenchWay reported that 80% of respondents found annual performance reviews somewhat or very helpful.

The problem is only 30% of techs surveyed said they meet with their manager one-on-one every week, and the same amount never meet one-on-one with their manager.

Training and mentorship

Lack of guidance and mentorship in the shop appears to be another major weak spot. In the latest WrenchWay survey, three out of five respondents said their shop doesn’t have a mentorship program, despite how positive mentorship can be for both mentors and mentees. Other surveys have indicated shops should strive for better training programs. A 2023 survey by ASE’s Training Managers Council revealed that 55% of fleet technicians didn’t have adequate access to training.

Conversely, boosting mentorship appears to stave off turnover. According to CNBC and SurveyMonkey data, 91% of workers who had a mentor are satisfied with their job. (Special thanks to Marshall Sheldon, a mobile diesel tech for MHC Kenworth in Macon, Georgia, for providing that peachy stat.) And Sun Microsystems found that mentors are six times more likely to be promoted.

Love’s Travel Stops has taken a proactive approach to both with its Truck Care Academy, an accelerated training program for new Love’s Truck Care and Speedco techs. The five-week program teaches diagnostic, repair, and troubleshooting techniques, and includes job shadowing for three months after they graduate from training.

Read more: Keys to tech mentoring: Lead by example then let 'em cook

“We learned quickly that you couldn’t just toss them to the wolves. We had to really help them grow,” Chuck Ralston, senior manager of Love’s Truck Care Academy and mechanical services, recently told Fleet Maintenance. “It cut turnover exponentially. People only leave when they get frustrated about something. Nobody wants to be frustrated at work. So we give them that confidence … If you give somebody a path, they seem to stick around.”

More career development

Advancement and promotions are the most powerful retention tools a shop can leverage to keep good techs. The I-CAR study noted: “While 96% of technicians who are ‘very satisfied’ with their career advancement opportunities are overall very satisfied, just 13% of technicians who are very dissatisfied with advancement are.”

To be qualified for advancement, shops need to help techs build skills. In any job, that has a positive impact on retention as well, concluded Research by CultureAmp, a human resources software provider. Their research of 175 various business teams found developmental opportunities far exceeded pay and ability of managers regarding an employee’s commitment to a company.

Pay drives 11% to leave a job, while management impacts 12% of these decisions. Overall leadership came in at 28%. But the top by far was opportunities for development at 52%.

This outweighed even how good—or bad—their boss was. Though CultureAmp data indicated great managers combined with great development opportunities had the best commitment rating at 66%, with above average opportunities and bad managers at 56%. But if the ability to develop skills is below average, neither a good nor bad manager makes a difference, with commitment at 35% in both cases.

About the Author

Alex Keenan

Alex Keenan is an Associate Editor for Fleet Maintenance magazine. She has written on a variety of topics for the past several years and recently joined the transportation industry, reviewing content covering technician challenges and breaking industry news. She holds a bachelor's degree in English from Colorado State University in Fort Collins, Colorado.

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.