High performance piston ring sets hone cylinders

“While unquestionably vital to performance, the piston ring is sort of the poor stepchild of the high-performance engine,” said Keith Jones, technical expert at Phoenix-based Total Seal. “They get blamed for just about everything. If there is a compression problem, it’s the piston rings. If there is oil consumption, it’s the rings. I wouldn’t be surprised if the rings got blamed for a flat tire on the way to the race track.”

Jones knows a lot about piston rings and racing. Since 1967 his company has been manufacturing high-performance piston ring sets installed in racing engines used in competition events ranging from IRL (Indy), NASCAR, World of Outlaw sprint car and other racing classes. To stay informed of customer needs and satisfaction, Jones actively solicits feedback from customers, particularly questions concerning performance and critical installation procedures.

Except for its standard automotive line, the countless different ring sets that Total Seal offers are for customized engines, each having many individualized requirements, including cylinder block materials and piston ring designs. Of those, it is particularly important that the piston rings precisely maintain 100 percent contact with the walls of the block’s cylinder bores. Otherwise, performance problems such as compression blow-by and oil leakage can cause severe, if not catastrophic, problems.

Providing the needed consistent contact between piston rings and cylinder bore almost always requires resurfacing of the bores in racing applications, either because the bores are not perfectly round, have been damaged by previous ring or piston failure, or other wear factors. In any such cases, resurfacing the bores can be a challenge.

“High-performance engine blocks have changed a great deal over the past couple of decades,” Jones said. “One of the most noteworthy changes is the hardness of the block metal, which can be several times harder than it used to be. This has dramatically affected cylinder ring installation requirements because it is now crucial for the customer to achieve proper ring fit inside the cylinder bore at the time of installation.”

Jones explained that in the old days, when engine blocks were composed of relatively soft metals (e.g., 150 Brinell hardness), installers could usually rely on piston rings to adjust to cylinder bores by wearing into the bore surfaces after installation. However, this approach is no longer realistic because today’s engine blocks are much harder (e.g., 330 Brinell), while the high-performance rings are considerably softer with lower tension. The combination simply doesn’t permit that kind of “break-in” technique.

To facilitate proper cylinder bore surface preparation and piston ring-to-bore fit, Jones and other high performance ring manufacturers and distributors recommend the honing of cylinder bores to exacting tolerances (within a few microns). This procedure ensures that excessive compression blow-by and inadequate cylinder bore oil retention are avoided at the outset.

Since bores differ widely according to block hardness, design and engine wear conditions, the proper honing of bore surfaces could become a tricky situation. However, Jones finds that rather than taking a fairly difficult and cumbersome approach of honing with conventional stones, he recommends the Flex-Hone produced by Brush Research Manufacturing in Los Angeles.

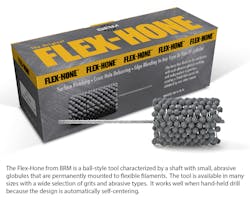

The Flex-Hone is a ball-style tool characterized by a shaft with small, abrasive globules that are permanently mounted to flexible filaments. The tool is available in many sizes with a wide selection of grit material. It works well when hand-held because the design is automatically self-centering.

The cross-hatching capabilities of the tool are integral to the cylinder bore surfacing requirements of most internal combustion engines, ensuring that proper oil retention will be maintained in the cylinder bore walls at all times.

Using the tool, parts such as carbide bushings, bore sleeves, hydraulic and pneumatic cylinders, and other cylindrical cavities can be surface finished on the production line – or resurfaced in the field – using a relatively inexpensive tool that requires little set-up time.

“We recommend this type of hone because it works very well, is easy to use with a hand-held drill motor, and is really fool-proof for the average consumer that is not an experienced machinist,” explained Jones. “It’s really easy to screw up with an average rigid-style hone, but it’s very difficult to screw up with a Flex-Hone.”

The Flex-Hone is available in 11 abrasive types and eight grits. In the case of most automotive combustion cylinders, 120 grit works for older cast ring sets or where the cylinder has been re-bored and is a little rough. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A 320 grit, and even sometimes as fine as 400 grit are often used in high performance applications with high performance ring sets.

Because the Flex-Hone is available in a variety of sizes, as well as abrasives and textures, Jones often refers customers to Brush Research for additional technical advice or specific product and process recommendations.

"We provide this type of support all the time,” said Miller. “Total Seal’s recommends using our LEVIGATED ALUMINA (super fine) abrasive in one application which is a little different from other requests we get. Total Seal does their homework and have found a combination that works best for their rings in harder block materials.We are asked to produce many different surface topologies which is not a problem with the Flex-Hone.”

“For example, we have a customer that builds engines for the high-performance marine industry that wants a surface finish that is quite different from automotive applications. So, we ask them what Ra, Rk [roughness factors], and other surface characteristics they want to achieve, and then we identify and ship them with the tool that will meet those specifications.”

In addition to special, customized applications, this flexible hone is also used in production environments, including with CNC equipment.

In a production example that required a custom solution, a diesel engine remanufacturer utilizes Flex-Hones in a two-step operation to resurface cylinder bore liners.

“For that application we recommended one tool, a 120-grit model, to produce the crosshatched surface with ‘valleys’ that would provide the necessary oil retention,” Miller explained. “For a second honing step, we provided a 600-grit model that put a nice plateau finish on top of the deeper cross-hatching. Through this two-step process, the remanufacturer was able to bring their cylinder liners back to specification.”

For more information, contact Brush Research Manufacturing, Brush Research Mfg. Co., Inc., 4642 Floral Drive, Los Angeles, CA 90022; Phone: (323) 261-2193; Fax: (323) 268-6587; email: [email protected] or visit the web site: www.brushresearch.com