More and more government, private and for-hire fleets are looking for ways to improve sustainability because it’s what customers and communities are demanding.

For example, Walmart has integrated a sustainability index (a measurement system used to track the environmental impact of products) in its supply chain. By the end of 2013, the index is expected to include more than 300 product categories and as many as 5,000 suppliers.

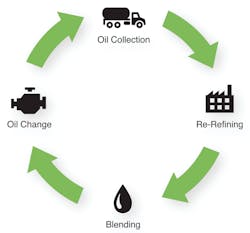

Changing the Oil Change

While protecting engines with premium engine oil is job number-one, fleet maintenance professionals can do their part in attracting or keeping the favor of customers and others by simply changing the way they change oil. By switching to a greener, more sustainable, re-refined engine oil, fleet professionals can reduce a company’s carbon footprint and score points with customers, communities and company executives.

And doing so doesn’t mean you have to sacrifice performance and engine protection. Today’s top-quality re-refined heavy duty diesel engine oil has been tested and shown to meet or beat oil made from virgin crude.

Benefits to be Gained

The reduction in greenhouse gas (GHG) emissions from switching to re-refined engine oil may surprise you.

For example, a fleet that uses 250,000 gallons of Safety-Kleen’s EcoPower brand of re-refined engine oil per year could reduce GHG emissions by more than 1,900 metric tons per year. That’s equal to growing more than 49,000 trees for 10 years in an urban environment.

Another environmental benefit that appeals to customers and communities is that the process to create re-refined engine oil requires up to 85 percent less energy than engine oil made from virgin crude. In fact, just one gallon of reclaimed engine oil produces the same amount of engine oil as 42 gallons of crude.

This 42:1 ratio also helps reduce the nation’s dependence on foreign oil.

By making a change for the better, a fleet maintenance team can protect engines and also become green contributors to the fleet and company. It’s a simple thing to do with a big impact on the environment, on customers and on communities, without compromising on the most important job for an engine oil - engine protection.

Engine Protection

How does re-refined engine oil deliver on engine protection? In the case of EcoPower, the leading re-refined engine oil brand, it meets or exceeds the rigorous API tests and requirements for its 15W-40 and 10W-30 CJ-4 Heavy Duty Diesel Engine Oils categories.

According to the API, engine oils that meet CJ-4 requirements are especially effective at sustaining emission control system durability where particulate filters and other advanced aftertreatment systems are used. Optimum protection is provided for control of catalyst poisoning, particulate filter blocking, engine wear, piston deposits, low- and high-temperature stability, soot handling properties, oxidative thickening, foaming and viscosity loss due to shear.

Performance Tests

Another way re-refined engine oils prove their quality is with real-world engine tests. It’s a good idea to request results of these tests before you make a switch in the engine oil that your fleet uses.

In an independent study, EcoPower showed excellent performance over the course of a million miles in real-world conditions with two over-the-road trucks in long-haul, fully-loaded service. The two rigs traveled one million miles each using only EcoPower for engine oil.

The trucks' engines, 2007 Cummins ISX 450-hp horsepower EGR models, were subjected to oil drain intervals of 40,000 to 50,000 miles, compared to the manufacturer-recommended 25,000 miles. At each drain interval, the oil was analyzed for the presence of wear metals, acid neutralization and viscosity maintenance.

Tests showed that EcoPower HD 15W-40 CJ-4 was as good as, or better than, two leading premium heavy duty oils made from virgin crude.

Details of the test, including video and charts, can be viewed at www.ecopoweroil.com/fleets/millionmiles.

Extending Oil Change Intervals

Many fleets would like to extend their oil drain intervals. Doing so would save time and money. Plus, changing oil less often is also better for the environment.

The best approach is to conduct an oil analysis to determine the optimal oil change interval for your particular fleet.

Re-refined engine oil is up to the task of extending oil change intervals as well.

To illustrate, a fleet wanted to extend its oil change interval with EcoPower re-refined heavy duty diesel engine oil. It was extreme service, with trucks subjected to stop-and-go operation in cities with a great deal of idle time.

An oil analysis was conducted first. The analysis showed how far the drain interval could be extended while protecting the engines and the environment. As a result, this customer was able to increase the oil interval by 50 percent and helped the organization meet greenhouse gas emission reduction goals that were important to its customers and others - all without compromising engine protection.

The Right Thing to Do

These days, customers and communities are demanding that companies pursue sustainability. For supply chains and fleets, there’s a real opportunity to be a valued partner by changing processes to more sustainable options.

For fleet maintenance, that opportunity is as simple as changing the way you change oil.

About the Author

Curt Knapp

Executive Vice President, Marketing and Oil Re-Refining Sales, Safety-Kleen

Curt Knapp is executive vice president, marketing and oil re-refining sales, for Safety-Kleen, the largest collector, recycler and re-refiner of used oil in the world (www.safety-kleen.com). Safety-Kleen’s EcoPower re-refined engine oil uses up to 85 percent less energy to produce than oil made from virgin crude, reduces greenhouse gas emissions and meets or exceeds the toughest industry standards for engine performance and protection (www.ecopoweroil.com).