In this article, you'll learn about:

- How renewable diesel can support a fleet's sustainability goals

- How renewable diesel can impact a fleet's mileage and equipment

- Blend considerations and accessability concerns for renewable diesel

Emissions advantage

Given that broader understanding of what “carbon footprint” means, said Kevin Otto, electrification technical lead at the North American Council for Freight Efficiency (NACFE), RD even matches up well against battery-electric solutions. “An EV puts out virtually nothing while in operation. The trouble is getting the electricity to the vehicle and keeping that vehicle charged,” Otto pointed out.

“RD clearly reduces CO2, so it can help a fleet reach certain sustainability goals pretty quickly—and much better than a battery-electric vehicle,” added Jeff Short, VP at the American Transportation Research Institute (ATRI).

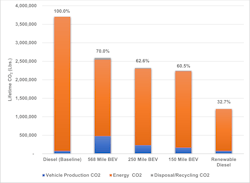

Short was instrumental in the development of ATRI’s report, “Renewable Diesel: A Catalyst for Decarbonization.” ATRI research suggests that the per-truck lifecycle CO2 reduction of RD vs. petroleum diesel is 67.3%. When comparing a 568-mile-range BEV to a truck burning petroleum diesel, the reduction is only 30%. A 250-mile-range BEV, which is more likely for a Class 8 tractor-trailer application, only reduces per-truck lifecycle CO2 by around 37% (see chart). RD has a clear advantage over BEV.

When focusing exclusively on emissions coming from a diesel engine, Cummins testing suggests RD could also have a slight advantage.

“Generally speaking, we can say particulate matter (PM) is reduced fairly significantly when burning RD as compared to petroleum diesel,” said Jeff Klopfenstein, materials science — corporate fuel SME — technical advisor at Cummins. “NOx emissions, depending on the duty cycle and how the engine is running, typically run about even, although some tests show RD to be slightly better. The other engine emissions are also pretty well in line.”

Fuel economy is another factor that impacts engine emissions. But RD has a slight disadvantage here.

“The energy density of RD is less than traditional petroleum-based diesel,” Ulrich said. “That is something fleets should factor in. Even though RD performs a lot like diesel, you’ll have to burn more gallons to go the same distance.”

A comparison study of R100 and mixed blends with petro diesel produced by California Air Resources Board found “statistically significant increases in fuel consumption per bhp-hr for all of the biofuels, ranging from 4.8% for R100, 6.0% for R65/B35, and 57% for R50/B50.”

Paccar’s 2024 MX-11 and MX-13 Operators Manuals also point out that energy content by volume is lower than that of petroleum diesel, which can reduce fuel economy. These are all factors to consider when determining if RD will help a fleet meet its overall environmental and economic goals.

Maintenance and performance

Another advantage of RD is that because it is a drop-in fuel, maintenance protocols in shops are largely unaffected.

“Cummins states in its literature that there’s virtually no impact on engine longevity or performance—as long as the fuel meets our requirements,” Klopfenstein pointed out. “There are heavy-duty engine platforms, like our X15, where the engineering team recommends checking the valve lash at half the specified service interval. That is due to the low amount of soot generated in the combustion of RD. Past evaluations found that some amount of soot helps lubricate these components when using conventional diesel. So when switching to RD, there is a need for at least increased inspection due to the potential increase in wear.”

Fleets should also be aware of the cold-flow properties of the RD they are using. “There’s some variation of these properties based on fuel producer,” Klopfenstein said. “I’ve seen some problems when trucks fill with RD in a warm-weather area, and then travel to higher-altitude zones where it’s colder.”

Marci Ballard, director of corporate development at Christensen, a fuel and lube supplier based in Washington state, agrees. “Fleets should talk to their fuel supplier about blending options, maybe a 50/50 blend, when driving in colder areas,” she said. “Of course, since it’s a drop-in replacement, the fleet could always fill up with regular diesel if they’re worried about the outside temperature on a certain haul.”

United Shippers is one of Christensen’s fleet customers who made the switch to RD. Alex Sak, operations manager for the roughly 80-truck Oregon branch, helped lead his branch’s transition.

“We had been running B5 for a while because B5 and B20 had been our only options in Oregon due to regulation,” Sak said. “We had a lot of problems when we’d tried B20 at first because that 20% organic compound would grow in the tank and cause issues with the fuel. B5 was better, but we were still having issues with DPF clogging.”

When the price of B5 spiked last year, Sak called Christensen to talk about alternatives. At that time, R99 (a 99% RD blend) was running about 40 cents cheaper than B5. He made the switch to RD in July 2024.

“We gave all of our drivers a heads-up and asked them to provide feedback,” Sak said. “Several drivers reported that they could now pull some hills in eighth or ninth gear, where they used to have to drop down to seventh or sixth. They also liked that RD is clear and doesn’t smell like diesel.”

The impact on aftertreatment systems has been the biggest benefit.

“We noticed that our trucks stopped having to come into the shop for forced regens,” Sak said. “We also stopped having to buy all these replacement NOx sensors, outlet sensors, and temperature sensors. It made sense. We no longer had that organic compound in our fuel that was causing issues when we were running biodiesel blends.”

According to Ballard, some of Christensen’s fleet customers have made the switch to RD from regular petroleum diesel. That has been the case in Washington state where biodiesel blends are not required like they are in Oregon. Still, some fleets see the benefits of RD.

Peter Zonneveld, president of Neste US, said RD also has some storage advantages compared to biodiesel. RD doesn’t contain oxygen, so it doesn’t attract water.

RD also has a high cetane index of 70-plus, compared to anywhere from 40-55 for petroleum diesel. That results in a cleaner burn and more power. “We have anecdotal evidence from customers saying that their trucks shift better, have better cold-start capabilities, and simply feel like there’s more power,” Zonneveld shared.

Regardless of where they are located, fleets can’t begin reaping the benefits of RD unless the fuel is readily available—and at a price that doesn’t break the bottom line. Regretfully, Sak said his bottom line recently broke. Due to supply challenges, the price of RD has more than doubled for his fleet.

“Now that we’ve had to switch back to B5, some of our regen problems have returned,” Sak said. “We are hopeful that we’ll be able to switch back to RD sometime in the future.”

“We believe RD is a great solution to help decarbonize the transportation industry,” Zonneveld added. “When you look at data published by the Engine Technology Forum, 75% of all new heavy-duty trucks sold will still have a diesel engine in 2032. If the industry wants to be more sustainable, we need to think about how we can decarbonize all of those existing diesel engines. RD is a very practical solution.”