Heavy-duty engine manufacturers aren’t the only ones being affected by the EPA’s stringent new emissions standards for MY 2027. Oil marketers are fervently working to develop a new class of engine oils (PC-12) that will deliver sufficient hardware protection for tomorrow’s engines while also helping engine makers satisfy the emissions and performance requirements of the new EPA standards.

“The most critical requirements include a huge reduction in NOx emissions, 75% lower than currently allowed,” said Walt Collier, commercial sector manager for Chevron. “In addition, Class 8 trucks will now be required to stay compliant with the new emissions standards for 800,000 miles, a near doubling of the current useful life requirement. For lubricant producers, the standards also call for further reductions in phosphorous and sulfated ash that can impair emissions control systems and diminish fuel economy.”

Lower viscosities are coming

The 2027 EPA standards also call for a reduction in GHG (greenhouse gas) emissions, i.e., CO2. One of the best ways to accomplish that is to reduce fuel consumption. Engine oil can play a role in this by helping to improve fuel economy through lower viscosity grades.

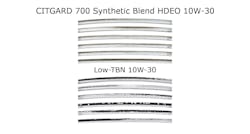

The industry has already seen substantial improvements in fuel economy with previous oil classes. It is generally accepted that switching from a CK-4 15W-40 to a 10W-30 can help improve fuel economy by 1-2%. Moving from a CK-4 10W-30 to an FA-4 10W-30 could yield another 0.5-1% gain.

Where might things be headed with the new PC-12 class of oils in 2027?

“Within this category, we are looking closely at the potential for SAE 20-weight oils, which will be a big step for the industry,” Collier said. “While this concept is new to us in North America, Europe has been a few years ahead of the curve. Some OEMs now require 0W-20 viscosities in their factory fill lubricants. U.S. OEMs that have partners or working relationships with European engine builders are studying their experience carefully and applying those learnings in their new engine designs.”

According to Paul Cigala, senior commercial vehicle lubricants applications engineer at ExxonMobil, one of the new 20-weights could help fleets see another 0.5-1% fuel economy improvement over an FA-4 (10W-30).

Read more: Making your fleet more adaptable with oil analysis

“Low viscosity reduces drag within the engine, as well as pumping and rotational losses,” explained Darryl Purificati, senior technical advisor for OEM/Automotive at Petro-Canada Lubricants, an HF Sinclair brand, and chair of the API lubricants committee. “New lubricant technology can also help to improve the friction characteristics of an engine oil.”

Additionally, because viscosity decreases as the oil heats up, engine manufacturers can further gain engine efficiency by controlling operating temperatures. This is why oxidation stability is becoming increasingly important.

“Improvements in oil oxidation stability can facilitate this strategy by maintaining the life of the oil,” said Karin Haumann, OEM technical manager at Shell Global Solutions. “Oxidation stability improvements were included in CK-4/FA-4 and will further be improved with PC-12.”

To that point, Haumann is also anticipating increased use of synthetic base oils.

“Improvements in oxidation stability are partly the result of improvements in synthetic base oils,” said Haumann, who is also chair of the PC-12 category development team for API. “Synthetic base oils are molecularly more uniform and perform better at both ends of the temperature spectrum. As base oil quality improves, we can provide a finished product that has better oxidative stability. So when you think about it, low viscosity and synthetics really go hand in hand.”

Adapting the additive package

An engine oil’s additive package is a huge part of its anti-wear capability. The EPA is throwing a wrinkle into things by requiring aftertreatment systems to last considerably longer.

“We can no longer think of the aftertreatment system as something in the background that we can design around,” Collier said. “We must look at the engine and EATS as a whole, and formulate lubricants that will protect both components.”

For instance, much of the ash buildup in a DPF is attributable to non-combustible additives in the engine oil. “Reducing the sulfated ash content in the engine oil can help prolong DPF service life and extend maintenance intervals,” Collier said.

“Some additives can be harmful to aftertreatment system components if the engine oil is consumed in the combustion chamber,” Haumann added. “While CK-4 and FA-4 currently have formulating limits on sulfated ash, phosphorus, and sulfur, PC-12 is targeting further reductions of anywhere from 10 to 25%. We as the API product development team have agreed to targets we think are appropriate and achievable.”

Satisfying those lower targets doesn’t mean those important additives will be reduced to a level where engine protection is compromised. “It’s not like we’re reducing the additive chemistry by half,” said Bill O’Ryan, senior manager for EOLCS/DEF at the American Petroleum Institute (API), the organization that spearheads the development of new engine oil classes. “Plus, there is going to be extensive testing before these oils are made available.”

“The new oils will need to have improved oxidation performance, as the limits of the Volvo T-13 oxidation test have been lowered,” added Steve Bowles, Citgo STLE certified senior oil specialist and oil monitoring analyst. “They’ll also have to perform well with wear protection because a new protection test has also been added (Detroit Diesel DD13 scuffing test). Finally, the new oils will have to be compatible with the current seals. A new seal, the HNBR seal, has been added to the testing.”

There could also be a little give and take to make sure a new oil’s anti-wear capability holds up. “The new oils could be formulated with lower levels of phosphorous and zinc, but increased levels of boron and molybdenum to help maintain the necessary level of wear protection,” ExxonMobil’s Cigala said.

Status quo on standard PM’s

Aside from allowing fleets to use a low viscosity grade previously unheard of, PC-12 oils aren’t expected to necessitate any meaningful changes to standard maintenance protocols.

“Oil drain intervals should be similar to the CK-4 and FA-4 levels seen now, as the new oils will have excellent oxidation control and wear protection,” Bowles said.

“With some of these new engines we’re going to see, I wouldn’t be surprised if 75,000 becomes the norm,” Cigala added.

Oil sample analysis will continue to be an important tool for fleets, especially those looking to extend their ODIs. When 20-weight oils become a reality, Shell’s Haumann said fuel dilution will be an important element to look for in an analysis report. “The viscosity is already low, and you don’t want it going any lower due to fuel dilution,” Haumann explained.

Fleets are still more than two years away from having to think about those 20-weight oils, though. In the meantime, oil marketers will continue to refine their new PC-12 formulas, test them in the lab and on the road, and make sure they meet the expectations of both the EPA and their fleet customers once 2027 rolls around.