Success in heavy duty diagnostics requires combined experience and disciplined procedures

“That’s how we’ve always done it!”

How often has the new tech heard these words from the old guard who have been working on trucks for decades? Sometimes that attitude can stifle inventiveness or sometimes it answers the basic question “how do you do it?” It’s the same in almost every work environment – the push and pull between the old way and the new.

When diagnosing problems with today’s trucks, simply relying on the tried and true can lead technicians to overlook complex issues that are likely in play when something goes wrong. Following standard diagnostic procedures can keep fleets from going off the rails and down a wayward track in finding the problem. The best practice is to use both approaches, combining what has always worked supplemented by new diagnostic technology.

Never assume

Being overly familiar with routine problems and typical fixes may led to misdiagnosis or not identifying the root cause of the problem, setting up a repeated failure and additional downtime for returned repair work. Fleets consistently say that not getting a vehicle repaired right the first time is a particular annoyance. Assuming that a particular problem is always the result of a specific set of circumstances is always risky.

Experienced technicians are a real bonus for any vehicle repair facility, and relying on their learned expertise can be the bedrock of the business. New techs, without that experience, are taught to follow a rigorous diagnostic path when learning how to fix commercial vehicles. Skipping steps can easily lead to the wrong conclusion and waste time and resources in the process. Step-by-step diagnostic procedures can be time-consuming but generally will help to resolve concerns accurately with the least amount of effort.Still, there is no doubt that first-hand knowledge of failure patterns and the typical fix can provide a great head start in diagnosing a problem. This is especially true if the problem is not easily determined. Nevertheless, it is important to not simply abandon proper diagnostic procedures by jumping to a conclusion based solely on experience, gut feeling or advice. There may actually be multiple reasons why a failure occurred. Making the effort to better understand the “why” behind the failure can be more crucial than determining “what” failed.

Another significant drawback to jumping to conclusions with diagnostics based on assumptions is that while the current repair may correct the problem, the cause of the problem may be completely overlooked and will likely occur again. There are times when fixing the assumed problem does not correct the actual issue on that particular vehicle.

What if there are no clear procedures?

What happens when the problem a tech is confronted with does not have any published diagnostic procedure? First, learn when and how the problem occurs — talking to the driver is a great place to start. This is especially critical with intermittent issues. It’s also good to review the vehicle's service history.

Then do some digging. Learn as much as possible about the system through the service information description and operation. TruckSeries from Mitchell 1 is an example of a resource for this type of truck repair information.

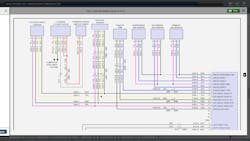

As an example, a complete review of the system wiring diagrams for circuits in the system can be helpful, along with the circuits that tie in through shared power and ground connections. When possible, harness routings should be noted to see potential movement or pinch points where damage may occur during operation. Also, be aware that splices tucked away inside a harness can be difficult to spot.

Sometimes it may be necessary to systematically check a circuit. When that need arises, put together a checklist to indicate a section of a circuit was inspected for an open, short to ground, short to power, or short to another circuit. There are additional things to check like whether there is any heat source near the circuit that may not be properly guarded or just routed too close.

The idea is that many required repairs take more than past knowledge to get them fixed right the first time. Nobody wants to have a vehicle in the shop any longer than necessary. A good diagnostic process combines learned knowledge about the systems and a healthy dose of open-mindedness.