Maintenance considerations for manual versus automated manual transmissions

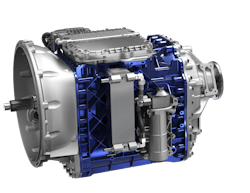

More of today’s Class 8 trucks are steering away from the traditional manual transmission. As fleets look to increase the pool of potential new drivers, improve fuel economy, and reduce maintenance costs, automated manual transmissions (AMTs) have become increasingly common.

According to Gary Pfister, manager of technical services for Eaton Vehicle Group North America, industry reports show that AMTs accounted for more than 75 percent of Class 8 market sales in 2019.

“Market share varies greatly by OEM and their production mix of linehaul versus vocational trucks,” Pfister points out. Eaton is a power management company whose broad product range includes transmissions and clutches.

While fully automatic transmissions have gained favor with Class 8 vocational trucks, the AMT has assumed dominance in the tractor-trailer segment.

Rich Nagel, director of marketing and customer solutions - air charging for Bendix Commercial Vehicle Systems, a supplier of active vehicle safety systems whose broad product range includes air treatment solutions and valves, is not surprised by the rapid shift toward AMTs in linehaul trucks.

“Driver convenience is a big issue,” Nagel says. “Veteran drivers typically don’t like AMTs because they like to have control. But look at who is driving trucks now. It is often somebody who did not grow up driving a truck. These new drivers need an AMT.”

Fuel efficiency and reduced maintenance are other benefits of an AMT.

Because an AMT is automated, electronics play a larger role. The gear shifting system is electronically controlled by the transmission electronic control unit (TECU).

“The system uses sensors monitoring things like inclination, temperature, gear position, road speed, air pressure, GCW [gross combination weight], and air resistance to consistently make the best possible shifts — similar to a good driver driving a manual transmission,” says Ashley Murickan, product marketing manager for Volvo Trucks North America, which offers a full range of medium to heavy duty trucks.

For a linehaul fleet, Murickan says this more efficient shifting can result in fuel savings of roughly 1 percent when compared to an average driver with a manual transmission.

Technicians could also see a reduction in transmission component wear and tear, as long as preventive maintenance is kept up to date.

“Electronics offer remote diagnostics capabilities, so a technician may be aware of an issue with the transmission before the truck is even brought into the shop,” Murickan says. “Fleets can benefit from the versatility of selecting different transmission software and shift strategies to best suit their respective applications, and this can be done over the air using Volvo Trucks’ Remote Programming service.”

Jeff Parietti, public relations manager for truck manufacturer Kenworth, says the Paccar 12-speed automated transmission also reduces maintenance costs and downtime. This AMT was introduced a few years ago and is available on both Kenworth and Peterbilt trucks suited to linehaul applications.

“The first lube change interval occurs at 750,000 miles and requires only 16 pints of oil — nearly half of what similar transmissions specify,” Parietti says. “A greaseless 430mm self-adjust clutch is maintenance-free, and the input shaft wear sleeve can be replaced quickly and easily without a costly and time-consuming teardown.”

Parietti says various built-in preventive maintenance features further improve reliability.

“The transmission fluid pressure sensor, for example, notifies the driver of low oil conditions to prevent gear burn-up,” Parietti says. “Smart prognostics for clutch replacement helps to better plan maintenance schedules. The electrical system is fully encased, minimizing exposure and corrosion to wires and connections. A vehicle oil-coalescing air filter protects the transmission system from contamination.”

Benefits aside, there are some things fleets need to keep in mind when maintaining an AMT.

Importance of electrical systems

AMTs are shifted either pneumatically or electrically. With respect to electrically shifted AMTs, battery maintenance becomes even more important.

Eaton’s Pfister says battery life normally ranges from 12 to 36 months on trucks with a manually shifted transmission. When operating a truck with an electrically shifted AMT, that range may top out at 18 months.

“Heavy electrical draw can affect battery life, which may be the case with an electrically shifted AMT,” Pfister explains.

Beyond battery maintenance, fleets should inspect the electrical system on a regular basis, looking for things like corrosion, wire chafing, and loose connections.

Whether the AMT is electrically shifted or pneumatically shifted, diagnostic information plays an important role in AMT operation. Pfister shares challenges fleets may face if a data link – which is the connection between different vehicle computer modules – is not operating properly.

“When not functioning properly, data links can cause undesirable vehicle launches and shifting issues after launch,” Pfister says. “Many new vehicles have an extremely high bus load on the data link, which can cause error messages if any of the electronic control units are improperly functioning or if the physical wiring of the data link has been compromised. Newer vehicles in the last few years have incorporated two different Baud Rate data links, 250K and 500K, which has lessened some of the issues we have seen in the past.”

It is important that technicians receive the proper training for the particular AMTs they are working on.

“Training is essential to accurately diagnose and repair these systems in a safe and timely manner,” Pfister adds.

High-quality air required

The air system is critical to pneumatically shifted AMTs. Technicians need to be especially vigilant with moisture and other contaminants in the system.

“Regular inspection and maintenance of the air dryer is essential,” Eaton’s Pfister says. “Many fleets do not replace the desiccant cartridge during routine maintenance; some wait until the dryer fails. When that happens, the air system has already been ingested with moisture, which can be catastrophic with an AMT. Moisture in the system can result in harsh shifting or even a loss of shifting completely.”From an air supply standpoint, Bendix’s Nagel says most of the industry’s focus has been on dry air over the past several years. With an AMT, the goal must be quality air, which extends beyond just keeping moisture out of the system.

“When I see product come back from the field, I often see what I refer to as a congealed mix,” Nagel says in reference to a water-oil mix along with some carbon buildup. “That’s why we’ve shifted from a focus on dry air to quality air over the past couple of years.”

Automated systems like AMTs are controlled by solenoid valves and electronic control units (ECUs), as opposed to air pressure and springs. That is why quality air is so important.

“With solenoid valves, a 12V coil creates a magnetic force,” Nagel explains. “Inside is an armature [push pin] that takes the magnetic field and holds the plunger open and closed. The sliding bearing inside of the armature has very tight tolerances. But with all of that is an increased chance of contamination.

“These valves also have smaller orifices,” Nagel continues. “These orifices are susceptible to contamination which can be a mix of oil passing from the compressor or oil passed with water if the dryer isn’t removing moisture properly. You could also experience particle contaminants or carbon-based contaminants.”

Ultimately, the shifting force of an electrically controlled valve is not as strong as a traditional pilot-operated valve controlled by air pressure. “With electrical power, you have a lot less seating force,” Nagel says. “You can’t just plow through a piece of dirt or gunk of oil.”

That is why oil-coalescing filters used in a vehicle’s air compressor have become increasingly important with AMTs.

“Essentially, any truck you buy today with an AMT will likely come out of the factory with an oil-coalescing filter,” Nagel points out.

Filter maintenance is important. With a traditional air dryer cartridge, Nagel says the typical failure mode is the desiccant cartridge getting dirty. Technicians need a different mindset with oil-coalescing filters.

“A brand-new oil-coalescing filter may remove 98 percent of the oil aerosols coming out of the compressor,” Nagel says. “But performance degrades over time. The filter will still work great, but not as well depending on factors such as compressor condition, duty cycle, and the way the truck is being run in general. Regardless, it’s a good idea for fleets to think about a two-year service interval on the oil-coalescing filter. That said, technicians need to keep an eye on it before that.”

Also on the topic of air supply, Volvo’s I-Shift AMT utilizes pneumatically actuated clutch and shift cylinder assemblies. This requires the transmission to have a dedicated air supply.“The transmission reservoir is supplied with air from the primary air system’s compressor, and is equipped with a reverse-flow check valve to prevent loss of transmission air pressure in the event of a primary system failure,” Volvo’s Murickan explains. “The reservoir is also equipped with a Schrader valve to allow the tank to be filled manually, if needed. All of this comes standard with specifying a Volvo I-Shift transmission.”

Preventive maintenance should confirm no leaks or blocks within air passages. “It is imperative that strict air system maintenance is adhered to,” Murickan adds.

Clutch considerations

With respect to clutches, Volvo’s Murickan says AMTs are similar to manual transmissions and offer similar warranty coverages. Preventive maintenance is also enhanced.

“AMTs are equipped with clutch wear sensors that alert the driver when a replacement is due,” Murickan says. “Technicians need to recalibrate the clutch whenever it is replaced. However, no manual adjustments are needed.”

Electric clutch actuation (ECA) clutches are engineered specifically for AMTs. They offer several performance benefits, but also introduce some new maintenance considerations.

“ECA offers the durability and performance necessary to withstand the high actuation conditions associated with AMTs,” Eaton’s Pfister says. “ECAs enable better launch and shift decisions through grade sensing, weight computation, and driver throttle commands. They also provide smooth engagement and a high fidelity of vehicle control, even in the most challenging applications.”

ECA clutches use a unique inertia brake called a low-capacity inertia brake (LCIB) to shorten shift cycles. Thus, it is necessary to grease the clutch-release bearing and cross shafts with the proper grease at the required intervals. “For most linehaul applications, the release bearing lubrication interval is 50,000 miles,” Pfister points out.

Because AMTs reduce or eliminate the potential for driver abuse, fleets are likely to experience less clutch-facing wear, which can extend the clutch replacement cycle.

“Fleets may also see extended lifecycles on various internal mechanical components such as sliding clutches and gears, as well as driveline components such as U-joints, differentials, and axles,” Pfister adds.

Newer-generation AMTs now utilize a 430mm single-plate, diaphragm-style organic clutch. According to Pfister, this style of clutch is designed to be maintenance-free and has fewer moving parts than its predecessors.

Lubes and intervals

With respect to lubrication, Volvo’s Murickan says AMTs and manual transmissions use similar transmission oil and oil drain intervals. Normal preventive maintenance inspections for fluid levels and leaks should be followed.

Some AMTs do require unique lubes. For example, Eaton’s heavy duty AMTs require Eaton’s PS-386 transmission lube, which is specially formulated to prevent wear and improve fuel economy. Fleets should always refer to manufacturer recommendations as to which lubes should be used in which transmissions.

“The Eaton Endurant AMT has an oil change interval of 750,000 miles due to the technology and architecture of the transmission,” Eaton’s Pfister says.

Filter maintenance may present some new items to consider. For example, the Volvo I-Shift AMT uses an oil filter that can be replaced with oil drain intervals. It also has an oil cooler to maintain optimal temperature.

The bottom line is uptime

According to Eaton’s Pfister, an AMT is no more challenging to maintain than a manual transmission. It’s just a matter of learning how they are different, and how their preventive maintenance practices are different. Training and proper tooling are key.

Some manufacturers offer web-based training to provide a fundamental understanding of AMTs on how they work, the primary components, and basic diagnostics.

“Instructor-led training helps prepare the technician for more complex procedures such as transmission overhauls,” Pfister adds.

In addition to training, technicians need the right tools to properly service an AMT. An AMT is a more technologically complex transmission. Up-to-date diagnostic software is essential.

“Eaton’s PC-based diagnostic software is called ServiceRanger 4,” Pfister relates. “Every AMT has a fault code hierarchy that helps technicians quickly identify the faults that are most important.”

Remote diagnostics capability is also important with an AMT.

A computer is essentially deciding when to shift gears and perform clutch actuations. If the transmission system fails to perform as expected, the ability to connect, diagnose, and repair from a remote location can help get the vehicle back up and running faster.

“Eaton’s remote diagnostics tool, IntelliConnect, helps monitor system performance, recognize fault codes, and initiate fault code action plans so fleets can better avoid catastrophic failures and costly downtime,” Pfister says.

According to Volvo’s Murickan, master technicians generally need to work on AMTs since they require the use of premium technology tools for software calibrations and special parameter settings. Cleanliness inside the transmission is also important, and special tools and procedures are required for that.

What the technician needs most is the understanding that AMTs are here to stay. For the fleet to fully realize the benefits, technicians must continue practicing religious preventive maintenance with an extra emphasis on things like air quality and electrical system integrity.