Breath of fresh air: Majority of trucks on road use clean diesel engine

As the transportation industry attempts get to zero emissions, data from the Diesel Technology Forum (DTF) indicate the majority of U.S. trucking fleets are already “near-zero.” This means that most trucks on the road were produced after 2010 (to comply with EPA standards starting that model year) and therefore deploy technology such as diesel particulate filters (DPFs) and selective catalytic reduction systems (SCR) to capture and treat nearly all Nitrous Oxide (NOx) emissions and particulate matter prior to exiting the truck and entering the atmosphere.

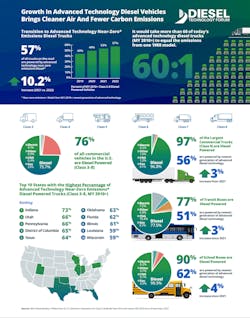

Near-zero emission diesel trucks account for 57% of the Classes 3-8 diesel trucks, with a 10.2% increase from 2021 to 2022, the DTF reported. About two out of every three diesel trucks are 2007 or older, meaning they are equipped with particulate filtration technology.

Along with adding aftertreatment systems, the heavy-duty trucking industry has greatly improved fuel efficiency through improved aerodynamics, engine oil formulas, and integrated powertrains, all of which improve mpg and reduce emissions. And recently, Navistar reported its International SuperTruck II demonstration vehicle achieved 16 miles-per-gallon fuel efficiency, a positive sign of how much more the industry can clean up its act using diesel alone.

Read more: Introduction to diesel exhaust aftertreatment

In 2027, new diesel engines will be even cleaner, as the EPA's new emissions rules go into effect. NOx levels, which are currently restricted to 0.20 g/BHP-hr., will drop to 0.035 g/BHP-hr., an 82% reduction.

Clean diesel vs. the rest

In total, there are more than 15 million Classes 3-8 trucks in the U.S., three-quarters of which are diesel. That means there are 6.4 million 2010 or newer diesel trucks operating today. Electric has a long way to go, as this zero-emission solution (which could still draw energy from a fossil fuel power plant) comprises 0.09% of the Classes 3-8 segment, for a total of about 13,500 units.

Clean diesel trucks own a 95.4% share in the Class 8 segment, while 2.1% CNG, 0.3% are electric, and the remaining 2% are gas or other fuel sources.

“Nearly 7 million new-technology diesel trucks are on the roads, delivering our goods and services with near-zero emissions,” DTF Executive Director Allen Schaeffer noted. “Nationwide, for every electric commercial truck on the road, there are nearly 1,100 powered by internal combustion engines.”

In California, where EV adoption is strongest, advanced diesel trucks outnumber electric trucks 125:1.

“According to this most recent analysis, internal combustion engines (diesel, gasoline, natural gas, and propane) power about 99.91% of the nation’s trucking fleet. As the trucking industry explores new fuels, including all electric and fuel cell technology, it is clear that diesel and other internal combustion engines are going to continue to play a dominant role for years to come,” Schaeffer said.

The top 10 states with highest percentage of clean diesel trucks are:

1. Indiana: 73.2%

2. Utah: (66.2%

3. Pennsylvania: (66.0%),

4. District of Columbia: 65.4% (ed. note: not a state, but DTF listed anyway)

5. Texas: 63.6%

6. Oklahoma: 62.6%

7. Florida: 62.3%

8. Illinois: 60.6%

9. Louisiana: 59.2%

10. Wisconsin 59.1%

California leads in EV deployments, but lags behind the national average, with 51.6%. That puts the Golden State at 35th place.

Maintaining clean diesel trucks

Because of this dominance, it is of the upmost importance that fleets and shops are prepared to handle maintenance issues related to aftertreatment systems.

“They get dirty. There are a lot of sensors. They can get clogged and there can be short circuits,” noted Bruno Gattamorta, chief commercial officer for Cojali USA, maker of the Jaltest CV diesel diagnostic tool.

This can of course lead to excessive forced regenerations of the system by a driver, or worse, extended downtime and additional costs to the fleet.

RoadWarrior Inc., a provider of aftermarket DPFs, advises that if a regen lasts more than an hour and/or has frequent forced regens, the filter might not be heating up enough to burn off the soot, leading to a clogged filter. That would require a trained technician to remove and clean the DPF, or require a replacement.

For more in-depth tips on what to look out for, check out our past reporting on aftertreatment maintenance:

How to diagnose fleets' biggest aftertreatment headaches: Aftertreatment systems have evolved a lot since their inception, yet still create headaches for the industry. The right balance of diagnostics and best practices can relieve that stress and promote uptime.

Look upstream to reduce DPF downtime: As frustrating as DPF regen issues can be, technicians should recognize that the DPF is typically the victim, not the villain.

What to look for during a DPF inspection: Diesel particulate filters work hard to keep the air clean but get dirty and damaged in the process. Here’s what technicians should know in order to spot potential issues and what can be done to fix and prevent them.

How aftermarket diagnostic tools can assist with DPF maintenance: Fleets can mitigate DPF-related issues when a diagnostic tool can handle everything from regens and resets to the pinpointing of hidden problems throughout the system.