P.S.I's Digital ThermALERT offers more wheel-end visibility

ORLANDO, Florida— Since Pressure Systems International (P.S.I.) has become part of Clarience Technologies, the tire management solution provider has been able to work more closely with the parent company's telematics experts, such as from Road Ready by Truck-Lite.This has led to the revamping of P.S.I.'s wheel-monitoring system, ThermALERT and the creation of Digital ThermALERT.

"We're able to share technology and innovations," noted P.S.I. marketing manager Craig Smith at the American Trucking Associations’ Spring Technology & Maintenance Council (TMC) meeting

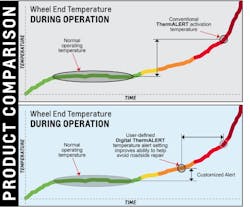

Craig explained that the original ThermALERT, which comes standard on Meritor Tire Inflation System (MTIS) by P.S.I., would simply alert a driver when the wheel end temperature rises 100 degrees F above normal, and would require the truck to pull over and receive service to prevent a wheel-off event.

Digital ThermALERT uses wireless sensor technology to provide real-time wheel-end temperature visibility through P.S.I.’s TireView LIVE portal, or a telematics communication portal such as Road Ready by Truck-Lite, another Clarience company.

The press plug installs at the critical heat area inside the spindle end, and a thermal conductor wire lead physically connects to the axle-mounted sensor, which transmits the data to the telematics system. The sensor's battery is replaceable. Fleets can customize the threshold based on their normal operating temperature for their duty cycles. The wheel ends of a truck that traverses more hills will likely get hotter than one operating more often in flat expanses.

The real-time monitoring and data analytics aspect determining root cause have already helped one fleet figure out why some of their trucks had unusually hot wheel ends.

Craig explained that the GPS data was about the same for each thermal alert, and those trucks all visited the same shop. It turns out the maintenance technician was misadjusting the brakes. Once the root cause was determined, the technician was able to receive training on how to do the job correctly.

This allows fleets to "get proactive" about their wheel-end maintenance and schedule service before a critical issue, Craig offered.

ATIS/MTIS training video

According to P.S.I., about three of every four new trailers are spec'd with autonomic tire inflation—and 2/3rds of them are spec’d with Meritor Tire Inflation Systems. Due to its popularity and importance in preventing dangerous blowouts and keepign tire costs down in general, P.S.I. has produced a new training video to help drivers better understand the MTIS with ThermALERT heat detection system.

The video walks viewers through how the MTIS system regulates air from the trailer tank before sending it to the tires via the axles and how a sensor in the control box activates the indicator light when air moves through the system or if a wheel-end thermal event is in progress. Finally, the video noted that a QR code will now be by the warning label for the trailer indicator light that will link drivers to the informational video.

“It's not necessarily just a driver training video, this could focus on technician training,” Smith reiterated. “And what this does is take the driver out of the equation. As a critical stakeholder, it allows you to train technicians [and] fleet maintenance people.”

According to P.S.I., about three of every four new trailers are spec'd with autonomic tire inflation—and 2/3rds of them are spec’d with Meritor Tire Inflation Systems.

TireView LIVE gets mobile app

PSI also released their new app, TireView LIVE, which is currently in beta testing and is set to launch on April 1, 2023 for both Apple and Android devices. The application focused on making most of the features from the standard, browser-based portal accessible on more portable devices.

The features brought over from the online portal include a drill-down of each vehicle by type, specific parameters to check on each vehicle, pre-trip inspection issues, post-trip analysis, and over-the-air updates if a sensor needs to be replaced.

“You can literally scan the QR code on all of our sensors and apply that to the wheel position needed,” Smith stated.