How battery thermal management systems protect EVs in cold weather

Record-breaking cold weather affected more than half of the United States population this past winter, but commercial fleet vehicles did anything but hibernate, keeping up with consumer, commercial and industrial demands no matter the weather.

But experiencing arctic events and cold snaps during some of the busiest times of the year raise questions for fleet operators about how the next generation of transportation, electric vehicles, will respond to freezing temperatures. After all, as experiences with smartphones show, temperature extremes in either direction negatively affect battery life and device operation. What happens when lithium-ion battery technology, the same as used in smartphones, is used to power commercial EVs?

Regulating the temperature of EV batteries, traction motors, and related electronics is a prerequisite for reliable operation. In this regard, EVs and petrochemical-fueled vehicles are similar. Cold weather can reduce battery capacity as the chemical reactions inside batteries slow down, increasing the internal resistance. This depletes the charge faster and reduces vehicle range. And keeping a respectable and consistent range is crucial for EV fleets, because commercial EVs, by definition, must be productive assets.

A lower-than-expected range would decrease their delivery radius in colder months, or force an electric truck to stop at a charging station during the day, which would cost valuable time and money. And on the topic of charging, did you know cold temperatures may also increase battery recharge times.

In short, battery performance is essential to reliably generating value. Thankfully, there’s a solution found in automotive thermal management. This technology is not new, and industry suppliers are adapting with technology and innovations in high-fidelity temperature control for EV components. As a result, electrified commercial fleet vehicles are becoming more viable across more market segments—even in the most severe environments.

Thermal management in the electric age

Thermal management is one of the least visible—but most critical—frontiers in EV transportation, because temperature impacts vehicle range, charging time, and the working lifetime of the battery. In commercial vehicles, these systems must efficiently manage temperature, respect space constraints, and reliably survive the harsh operating environments in which heavy-duty vehicles are deployed.

The battery pack needs to be maintained within a temperature window during charging and operation, typically 25 to 35°C (77 to 95°F), to deliver peak performance. A battery thermal management system (BTMS) will provide heating or cooling depending on the battery pack's temperature. On a cold winter day, a BTMS will heat the coolant that circulates the battery pack to maintain its optimal temperature. A key consideration in BTMS design is optimizing temperature control while minimizing power draw to ensure that work vehicles are as reliable as their predecessors and deliver the range required to get the job done.

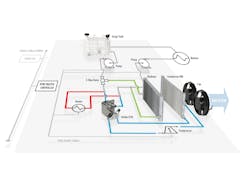

Modine has found its EVantage Thermal Management System can provide the needed control to ensure colder weather doesn’t put the freeze on a fleet’s operations. The system can integrate into any chassis design and combines state-of-the-art, proprietary Modine heat exchanger technology with tailored smart electronic products. With the included master thermal controller and Modine-developed firmware, the compact system has been proven to regulate battery temperature while minimizing power draw.

Keeping fleets on the road all winter

Commercial electric vehicles should include a BTMS designed to regulate battery temperature to maximize range and minimize charging time. A BTMS will do its job even in winter, but there are a few important things fleet managers and drivers can do to help optimize efficiency and uptime in cold weather.

While frigid temperatures may reduce vehicle range by up to 40%, nearly two-thirds of cold-weather range reduction can be attributed to conventional cabin heating. Drivers can easily mitigate this by using comfort functions with less power draw, like heated seats and steering when possible, and turning those functions off while not in the vehicle. Similarly, connecting to charging infrastructure whenever possible, especially in cold conditions, significantly benefits commercial EVs. When plugged in, a BTMS can maintain the battery pack’s temperature to avoid extremes. Storage condition is another stress factor impacting battery capacity and working lifetime. Vehicles stored in a heated or insulated space will require less time to warm to optimal temperature when service begins. To that end, indoor storage helps prevent battery degradation due to continued exposure to extreme temperatures.

As the seasons change

The southern parts of the country usually warm up before the midwest and northern parts do, which means that road-fairing commercial vehicles can experience a wide range of ambient operating temperatures in relatively quick succession. Just as a BTMS works to maintain optimal battery temperature in cold weather, it provides the cooling function in warm weather and as the battery self-heats during operating and charging cycles. The switch between cooling and heating, as well as the intensity of each, are managed automatically by the system. In this regard, the burden of seasonal change-over and maintenance tasks is actually lower for EVs.

While seasonal, temperature-related maintenance looks different for EVs than their internal combustion engine predecessors, fleets should pay attention to each vehicle’s diagnostic and maintenance software, including thermal management systems. Commercial EVs should include tools that help fleet owners perform the regular and preventive maintenance steps necessary to keep their vehicles running or troubleshoot problems quickly. Through proactive monitoring, the right software, and following maintenance schedules, fleet owners have the tools to keep EVs running year-round; that’s not all that different from the world of diesel and gasoline engines.

About Modine

Modine's motto is "Engineering a Cleaner, Healthier World." Building on more than 100 years of excellence in thermal management, we provide trusted systems and solutions that improve air quality and conserve natural resources. More than 11,000 employees are at work in every corner of the globe, delivering the solutions our customers need, where they need them. Our Climate Solutions and Performance Technologies segments support our purpose by improving air quality, reducing energy and water consumption, lowering harmful emissions and enabling cleaner running vehicles and environmentally friendly refrigerants. Modine is a global company headquartered in Racine, Wisconsin (U.S.), with operations in North America, South America, Europe and Asia. For more information about Modine, visit www.modine.com.

About the Author

Gina Bonini

Gina Maria Bonini is the Vice President and General Manager of Advanced Thermal Systems for Modine, a thermal management company with more than a century of experience developing solutions in the transportation and industrial heating and cooling verticals. In this role, she is responsible for leading the company’s commercial electric vehicle initiative and driving global revenue in the zero-emission mobility market. Previously, Gina served Tektronix as the General Manager of the Component Solutions Organization (CSO) and Technology Solutions Organization (TSO). Gina holds a BS in chemical engineering from the University of California, Berkeley, and an MS in electrical engineering from Stanford University.