Microwaves, mini-fridges, TVs and laptop computers. The modern heavy duty truck has all the conveniences of home.

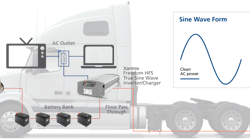

AC power is the preferred powering method, and trucks can be spec’d to handle the greater demands for electrical power. Those systems include inverters in a variety of power levels and types that take DC power from a battery and convert it to 120V AC that most modern appliances use. Inverters installed at truck manufacturing plants are hardwired so that AC power is available in all receptacles inside the sleeper cab.

Inverters should be initially selected based on continuous power output. But even if truck operators believe they have sufficient power to handle loads, and know how much demand they can put on the system, they can still get into trouble because of a phenomenon known as surge power.

Induction appliances like microwave ovens or appliances that use magnets or transformers need an initial power surge to start before dropping to “continuous power.” Depending on the appliance, the need for surge power could be up to 5 seconds. A 1,000-watt microwave, for example, may need up to 2,000 watts for a second or two before settling down to 1,000 watts to heat food.

Specs

If you spec inverters on your new trucks you’re safeguarded. Truck OEMs understand the concept of sufficient surge power. But aftermarket installation can be a different matter.

Lower quality inverters may be able to start a microwave a few times but may have shorter life expectancy, and in many cases, may not even survive the warranty period. The reason: some inverters do not have much in the way of built-in protection like premium brands.

There are two types of inverter designs: low frequency inverters (LFI) and high frequency inverters (HFI). HFI designs typically deliver a lower surge for shorter periods of time. Low frequency inverters have a longer surge duration up to 5 seconds for the most demanding loads.

To find surge ratings, we recommend going to the manufacturer’s website and searching out the continuous power and surge – and surge duration – specifications.

Size

Choosing the correct size inverter – based on what will be plugged – and surge capacity are critical, but not the only considerations. There is also safety and electrical performance.

When comparing inverters, look for a UL-458 rating, as noted in TMC (Technology & Maintenance Council) Recommended Practice 163, Power Inverter Selection Recommendations. Also, it’s advised that the inverter have a low battery voltage disconnect, along with the ability to re-charge a completely dead battery if plugged into shorepower.

By specifying an established and quality brand, fleets will have peace of mind knowing that their drivers are not only safe, but also have reliable power.

Installation

As for aftermarket installation of an inverter, it’s relatively straightforward task, but it requires a bit of research and some decision-making.

We recommend mounting the inverter under the sleeper bed, behind a protection bracket to prevent tools, chains and other gear from beating it up. Others considerations are to make sure the inverter is not in a compartment that’s going to get a lot of moisture. You also don’t want it real close to an outside access door.

Keep in mind that inverters “breathe.” Even though most top-quality inverters have a very wide operating temperature range, you don’t want it in a place where it’s going to get a blanket or luggage thrown on top of it. You want some air space so the inverter can pull in some air to cool off circuits.

Never put an inverter in an engine compartment, battery bay or any location containing fuel or flammable or corrosive vapors. Inverters are an ignition source and are incompatible with combustible fumes. If the only close location is in the battery bay, get bigger cables and move the inverter further away.

Convenience

How convenient it is to plug appliances and other devices into the inverter may also determine where and how the inverter is mounted. Ideally, inverters should be installed within 10’ of the battery bank. Moving it farther away may require larger DC cables to compensate for a drop in voltage over a longer distance. In most cabs, it’s a matter of having a sealed-access path from the floor of the sleeper, and then the cables can go right to the batteries below.

Some inverter models have a ground-fault interrupter receptacle on the front of the unit so appliances can be plugged directly into them. Wiring kits are also available to connect the inverter to receptacles installed in convenient places in the sleeper cab.

The best approach for installation is to leave the job to the OEMs. They have the knowhow and experience for issues like inverter location and cabling options. It’s not the least expensive option, at least initially, but it could pay for itself over the long haul in safety and reliability.