There is no substitute for a great diagnostic scan tool, but an oscilloscope can be a great complement, helping pinpoint the root causes of issues a scan tool merely alerts you to. In some cases, an o-scope will help discover failures a scan tool can’t even see.

Automotive oscilloscopes read voltage over time, something multimeters can’t do, making them powerful tools to test electrical system components for intermittent issues. They can also perform pressure tests and other diagnostic checks. These devices read and convert voltage data into a waveform presented on a screen as well, enabling technicians to look for irregularities that suggest a likely problem.

“An oscilloscope is really just a fast voltmeter,” explained Mike Eilbracht, a diesel training instructor at Diesel Laptops, a provider of diagnostic tools, repair and parts information, and technician training and support. “I guess you could say it’s a voltmeter on roids.”

Eilbracht noted that while these diagnostic tools have many benefits, learning how to use them takes patience.

“Whenever I talk to a technician who is new to oscilloscopes, I remind them that they will need to invest some time in order to get really good at it,” he said. “But I also remind them that they should not be intimidated.”

Choosing the right o-scope for your shop

There are several types of oscilloscopes out there, each offering something different to the user. Some are standalone handheld units. Others are scan tool add-ons or devices that connect directly to computers. They may have just one or two channels, or sometimes eight or more. Prices range from several hundred dollars to several thousand.

You’ll get what you pay for, of course, although that doesn’t mean a lower-cost scope would be a bad investment. ROI largely comes down to what you’re looking to do with a scope, as well as the experience level of the technicians who’ll be using it.

“You could always start with a more basic scope, and then go to a bigger system once your skills and knowledge further develop,” said Tom Bauman, director of sales, marketing, and new product development at Hickock Waekon, a manufacturer of oscilloscopes and other diagnostic tools for automotive and midsize truck technicians.

It also depends on what type of vehicles are being serviced in the shop.

“I believe a fleet would want at least four channels so technicians could test four circuits at once,” said John Forro, technical training specialist at Autel, a developer of intelligent diagnostics, detection, and analysis systems for automotive and commercial vehicles. “Four channels are often needed when determining timing-related signals and many other issues.”

Whichever scope a shop goes with, training and support are key.

“Hooking up the scope to the vehicle is the easier part,” said Travis McDonald, service manager at Diesel & Off Road Technologies in Soddy-Daisy, Tennessee. “Seeing and understanding what the waveforms actually mean is more challenging.” That said, a good oscilloscope provider will provide training resources for both.

Good oscilloscope providers have also developed product features that make scope diagnostics easier for technicians to perform.

For example, Hickock Waekon’s Auto Wave II handheld oscilloscope has a feature called Auto-Set, which automatically sets the voltage and time scale based on what the scope is seeing. According to Bauman, this allows novice scope users to quickly begin performing waveform diagnostics.

Premade, guided tests will also prove to be a valuable feature. Guided tests set up the scope for the technician, explain how to connect to a vehicle, perform the test, and evaluate the waveforms. Pico Technology, a leader in PC-based oscilloscopes, has more than 150 guided tests and 6,000 sample waveforms in its software library. On top of that, Diesel Laptops has developed dozens of guided tests specific to medium- and heavy-duty vehicles, along with hundreds of sample waveforms.

Read more: Tactics for lighting and electrical diagnostics and repairs

Diesel Laptops actually leverages Pico’s 4425A PicoScope in its oscilloscope kit. McDonald, who has been using Diesel Laptops’ four-channel scope for nearly two years, likes the tab at the top of the screen that allows a technician to see what a certain waveform should actually look like. That allows for a real-time comparison as a technician is checking waveforms from a vehicle.

O-scopes IRL

Oscilloscopes have been fairly prevalent in automotive repair for many years, but not so much in fleet maintenance shops. That has started to change over the past few years, which is why diagnostics providers like Diesel Laptops continue developing oscilloscope tools and resources specifically geared toward medium- and heavy-duty vehicles.

Navistar is one truck manufacturer that has recognized the potential of scopes in the heavy-duty world. The International truck maker assembled a group of dealership technicians in 2022 to begin testing an automotive oscilloscope from Pico Technology. Missy Albin, a senior lead technician at Taylor & Lloyd Inc. in Bedford, Massachusetts, was one of those technicians. She’s been a heavy-duty tech for 20 years and currently focuses on diagnostics and electrical work. The Pico pilot project represented her first encounter with an oscilloscope.

Albin has been using Pico’s four-channel 4425A Master Diagnostic Kit in combination with PicoScope 7 software on her laptop. As someone new to oscilloscopes, Albin said she has benefited from Pico’s guided diagnostic tests. One of those tests is cam and crank synchronization, which utilizes two channels.

“I was able to hook into the two sensors, run my crank session, and take both of those waveforms and overlap them on the computer,” Albin explained. “Then I could count the signals to see if I had an out-of-timed engine. I was actually able to diagnose a spun cam gear by one, two, or three teeth from those waveforms. Without the oscilloscope, I would have had to take the entire front of the engine apart. The scope makes it a much quicker diagnosis. The oscilloscope almost gives you see-through vision to what is actually happening mechanically.”

Another example of where a two-channel scope could come in handy is intermittent or inoperative windshield wipers and interior lighting. Say a technician connects a scan tool to attempt communication with the BCM (body control module) but is unsuccessful. Should the module simply be deemed faulty and replaced? Not so fast.

“With an oscilloscope, a technician could look at the schematic for that module and identify the CAN bus wires,” Hickok-Waekon’s Bauman said. “Then they could safely back-probe those wires to see if there is any voltage or communication going on. If communication is coming into the module but the scan tool can’t communicate with it, the technician knows the module isn’t working. But if no communication is coming in, the root cause may be the wire itself or somewhere in the wiring harness.”

McDonald said his shop is using its four-channel Diesel Laptops scope at least a couple of times a month. “We typically use it on those weird issues a scan tool can’t pick up on,” he said.

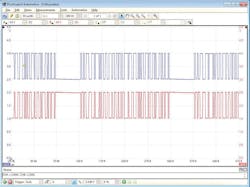

One of those “weird issues” occurred on a Chevrolet truck with a Duramax diesel engine. “It wasn’t reading park or neutral or anything on the dash, and our scan tool couldn’t communicate with the PCM at all,” McDonald said. In fact, the PCM, TCM, and ABS modules were all offline. McDonald decided to put the scope in the Datalink connectors to read CAN high and CAN low. After turning the ignition on, the waveform looked jagged and all over the place. A good waveform, in this instance, should look fairly square.

“That told me there was bad data on the system,” McDonald said. He proceeded to unplug the ABS module, but nothing changed. So he plugged that back in and unplugged the TCM. The PCM and ABS modules came back online, and the waveform looked normal. “That’s when I knew the TCM module was bad, so I replaced it,” McDonald said.

An oscilloscope can also come in handy when performing a relative compression test.

“Instead of removing glow plugs or spark plugs and installing a pressure gauge to perform a conventional test, a technician can simply attach a scope to any positive and negative wire, and crank the vehicle while preventing it from starting to get an overall idea of any compression-related issues,” Autel’s Forro said.

An oscilloscope once helped Diesel Laptops’ Eilbracht diagnose a faulty injection pump. The scan tool found two codes for fuel differential pressure and low rail pressure. After completing the recommended inspections, everything checked out okay. “I was baffled at this point because I knew all the injectors were firing,” Eilbracht said. “That made me a little curious about the pump.”

Before blindly tearing the pump apart, Eilbracht connected his scope to the rail pressure sensor as well as the fuel actuator to the pump. He also connected a separate pressure sensor to the low side of the injection pump. He took the vehicle for a test drive. When he returned to look at the data he’d captured, he noticed some staggered pressure drops and electrical spikes on the rail pressure signal every time an injector fired. After a little more investigating, Eilbracht was able to confirm that the injection pump was the problem. From there, he tore the pump down and discovered chewed-up cam lobes and a cracked pumping plunger.

“It turned out that my instinct was right in this case, and that the pump was the problem,” Eilbracht explained. “But what if I had been wrong? I would have spent a lot of time tearing that pump apart for no reason. The scope eliminated that guesswork.”

About the Author

Gregg Wartgow

Gregg Wartgow is a freelancer who Fleet Maintenance has relied upon for many years, writing about virtually any trucking topic. He lives in Brodhead, Wisconsin.