The Mating Game: Maintaining strong, long-lasting tractor-trailer connections

Fleets have several high-maintenance relationships when it comes to tractor-trailers, such as with aftertreatment and tires. But maintaining those relationships should not come at the cost of the simple-yet-vital connections that hold everything together—the kingpins, fifth wheels, and trailer lines. After all, you wouldn’t have a tractor-trailer without them, and if something goes wrong, you might end up with a tractor here and a trailer there.

This is why fleets and maintenance providers should never take trailer connections for granted; instead, keep a close eye on them if they want to stay hitched.

As the manager of A&H Truck Service, Nick Hoag has seen his share of trailer connection issues. A&H is a full-service shop just outside of Cleveland, Ohio, providing repairs, maintenance, and inspections for owner-operators and fleets,

“It’s important to be proactive so you don’t have issues on the road,” he said. “A lot of times, especially on trailers that are hooked up multiple times per day, simple things can cause problems.”

In many cases, those problems can be avoided with a little extra attention, Hoag added. For example, he related that making sure the fifth wheel is clean around the area where the locking jaws are located is a simple and effective practice.

“A buildup of grease will block the jaws from closing properly, especially in winter,” he said. “When truckers come in and say the fifth wheel won’t latch, it’s often because there’s dirt and grease in the jaws.”

When it comes to trailer air and electrical connections, Hoag advised checking gladhand seals for dry rot or missing gasket material to prevent air leaks. On electrical connections, inspect for worn ends, broken pins, and a snug fit. Additionally, inspect the spring that closes the door over the seven-way connector to make sure it shuts properly.

“Tight connections are the easiest place to start,” Hoag said. “If the gladhands and seven-way are loose, or you need a hammer to make the connection, something is wrong.”

To make sure nothing goes wrong and those connections stay strong, Fleet Maintenance caught up with several “mating experts” to guide you to a long-lasting relationship between your tractors and trailers.1. Start with routine inspections

The first thing to keep in mind is that it takes both sides for a successful union. Fleets and their drivers are responsible for ensuring proper tractor-trailer connections are made, noted Art Hobbs, branch operations manager at Great Dane Trailers. And there are several key connections to look at.

“It’s crucial to make sure connectors, fifth wheels, and lines are routinely inspected to ensure safety and compliance are maintained at all times when you’re on the road,” he asserted.

Not taking the time to ensure that a trailer is fully and correctly connected can lead to a dangerous and costly mistake. But according to Hobbs, it is completely preventable.

“A coupling issue that we see quite often happens when a driver backs under the trailer, gets out to make sure everything is locked, hooks up their air lines and wiring, and then doesn’t do a tug test before releasing the brakes to make sure the trailer is securely locked,” Hobbs said. “After all of the things they did on an almost-perfect coupling routine, they release the brakes, and the trailer takes off down the road.”

A trailer separation may cause damage to the landing gears, cross members, flooring, and even bottom rail. Hobbs said that “could easily cost thousands of dollars in repairs and five to seven days of downtime for repairs to be made, resulting in loss of revenue as well.”

Hobbs added that when backing under the trailer, the driver should always listen for the “click” sound when the fifth-wheel lock on the truck engages, and visually look at the fifth-wheel locking handle to ensure it is all the way in and locked. Lastly, before rolling up the landing gear legs, always put the truck in gear, and give it a tug to ensure the trailer is locked in place.

Improper maintenance on the road can lead to poor performance. Failing to lubricate a fifth wheel could alter aerodynamics, leading to a reduction in fuel efficiency.

“Look at the locking jaws on the truck’s fifth wheel for signs of wear or shiny spots that have not been lubricated properly,” Hobbs advised. “Also, visually inspect the trailer kingpin for signs of unusual wear or damage from being coupled to the truck.

“Check the electrical cord from the truck to make sure there is no corrosion present on the seven-pin connection, that there is no damage or cuts in the cord, and that it has enough slack in it to enable making sharp turns with no issues,” he continued. “And make sure both gladhands are connected securely to the trailer—that both lines are snug.”

Fleets also can leverage technology to help promote fifth-wheel safety. Rob Marsh, VP of truck product sales-OEM and Fleet at JOST International, said the company has two systems available.

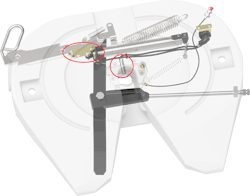

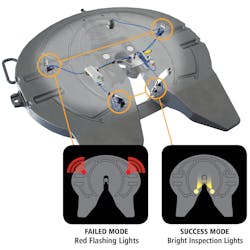

“The JSK37USK model is a two-sensor fifth wheel that senses the proximity of the kingpin and the handle to give feedback directly to the driver using an in-cab display,” he explained.Features of the JSK37USK include a visual lock indicator to confirm proper locking and an automatically engaging secondary lock to ensure security. With this model, the first sensor verifies that the kingpin is in the lock, and the second sensor indicates that the fifth wheel is locked and the release handle is secured.

To check these items manually, a driver would need to go under the trailer to verify that the kingpin was properly in the throat of the wheel and confirm, by a visual inspection, that the handle is fully retracted to the casting.

“Our newest design is called the Loc-Light fifth wheel,” Marsh said. “This model uses the same two-sensor system, but the positive/negative feedback is shown through a light underneath the handle. It also includes an audible beeping sound if it notices a negative connection and has an LED light to help a driver see if the locking bar is completely across the throat.”

The dual-sensor Loc-Light system is connected to a go/no-go light next to the handle. When the fifth wheel is properly coupled with the kingpin and the handle is in the locked position, the light will show solid green. If the system does not see both the handle and the kingpin in the correct locked position, it will flash red. The throat illumination light automatically turns on when the system is engaged.

2. Continue with maintenance best practices

Preventive maintenance plays a key role in ensuring proper and safe trailer connections, with proper lubrication at the top of the list. Hobbs pointed out that the fifth wheel on the tractor and kingpin on the trailer should be greased regularly to reduce friction and prevent premature wear. He also said that the electrical plug from the truck to the trailer should be coated with dielectric grease to prevent damage from corrosion.

Additional advice from Great Dane includes checking gladhand grommets periodically to make sure they remain soft and make a good seal. “They should be replaced when they become hard to prevent any air loss,” Hobbs said. “Adding screens to each gladhand will also keep insects from entering the air system when the trailer is not hooked to a truck.”

Tony Ryan, technical services and training manager at SAF-Holland, provided a series of kingpin inspection and maintenance recommendations. “We recommend that fleets follow kingpin manufacturers’ instructions for maintenance and replacement procedures,” he said. “Trailer upper coupler, or bolster plate, and kingpin inspection and maintenance are just as important as the inspection and maintenance of the fifth wheel.”

3. Keep air and electrical power flowing

The trailer’s air ride suspensions, brakes, and automatic tire inflation systems rely on the tractor air compressor, and certain trailer electrical systems feed off the truck’s battery. To prevent failure and a possible safety issue, those connections also need proper oversight and routine maintenance.

“Trailer electrical and air connections are subject to abuse and exposure to harsh conditions,” said Todd Howe, manager of product management at Lawson Products. “Heat, cold, moisture, dirt, oil, and grease all combine to interfere with good electrical conductivity, and cable and hose integrity.

“Improperly installed tractor-trailer electrical cables place mechanical strain on wiring, leading to failure,” he continued. “Electrical connection problems may exhibit themselves in dim, flickering, or failed lighting on the trailer and can result in a failure of the trailer’s antilock braking system.”

Poor air brake connections may lead to trailer pressure loss, immobilizing the truck, noted Andre Murphy, senior technical services engineer at distributor Lawson Products. “When connecting, be sure to align seals before rotating 1/4 turn, and be sure that the gladhand is fully locked in place and secured,” he advised.

“Always inspect the condition of gladhand seals on both halves when connecting and disconnecting, and look for signs of wear, cracks, or cuts,” Murphy added. “There should be resistance when connecting gladhands; if it seems loose, the seals need to be replaced.”

Murphy also advised using strain relievers or spring guards in areas where air-brake hoses are required to move and to ensure that coil hoses are properly secured to prevent wear caused by abrasion. “Always inspect hose condition when picking up and dropping trailers to look for kinks, cracks, and signs of wear,” he said.

“Inspect end fittings for signs of wear and evidence of strain or pulling at hose connection points,” Murphy continued, “and be sure to check the tractor side of the cable assembly, which is disconnected less frequently but where failures can occur.”

Technicians should also be aware of where dirt and contaminants can build up.

“The height control system for chassis and cab air suspensions acts as a catch-all for whatever debris makes it through a vehicle’s air system,” said Brian Kujala, VP of business development at Link Mfg., which produces the former Hadley Products line of height control valves. “That can lead to improperly functioning valves, which can cause unsafe weight-shifting load issues and higher costs due to premature wear.”

It’s important to start at the source of the problem, which means making sure air tanks are purged regularly to eliminate water and rust, Kujala advised. Automatic purge systems are not always found on trailer tanks, he also noted.

“Proper installation of air lines and connections ensure proper air flow,” Kujala added. “And if gladhands aren’t connected correctly and seals are not intact, not only could the trailer not be at the right ride height, it creates a leak path for water.”

Steve Howse, director of technical services at Tramec Sloan, said American Trucking Associations’ Technology & Maintenance Council (TMC) Recommended Practices, including RP 159, RP 435, and RP155A, can serve as the source of a valuable inspection checklist. Among the items included are the following:

- Check for audible leaks in lines, connections, and valves when the system is pressurized.

- Check for loose gladhand clamps and damaged or worn seals.

- Pull back the air line spring at gladhand and tractor connections, and inspect along the length of lines for kinks or restrictions.

- Check along the length of air lines for wear.

- Confirm that a functioning strain relief method is in place at the plug/cable attachment.

- Confirm that air and electrical lines are not sagging or dragging.

- Check that tender springs, clamps, pogo sticks, or slider bars are installed and function properly.

- Untangle lines to ensure free movement unless lines are purposely joined together.

- Check operation of all lights, ABS modules, and other electrical devices.

- Check along the electrical lines for wear. Inspect faded lines closely for fine cracks or brittleness in the outer cover.

- Check plug and socket terminals for wear and corrosion.

- Confirm that a functional strain relief method is in place at plug/cable attachment.

- Confirm that mated plugs and sockets are not loose and that the socket lid spring and plug/socket latching mechanisms function properly.

4. Avoid corrosive behavior

Among the many items in its series of Qwik Tech Tips, Phillips Industries covers combating electrical corrosion.

Fleet and drivers first detect corrosion problems in electrical, noted Ron Fay, technical support specialist at Phillips Industries. “That is because electricity causes the copper wiring within the electrical system to heat up and expand, and with fluctuating temperatures, it acts as a sponge, sucking moisture and contaminants further in, accelerating the corrosion process,” he said.In an experiment conducted at Phillips, Fay said, it took less than 24 hours for saltwater to wick through a 7-inch piece of copper wire, without varying temperatures that would expand and contract the wiring. “Imagine how much farther it could have traveled if an electrical current was passed through the wire?” he asked.

Additionally, this experiment was conducted with salt and water. Today, roads are treated with deicing chemicals such as magnesium chloride and calcium chloride that are 50% smaller than sodium chloride (salt), so they fit into tighter spaces. And they are highly soluble in water, creating finer mists of spray that coat more of the vehicle and have the ability to absorb moisture from any source, including the air in low humidity conditions.

Fay said that the following maintenance steps can help prevent damage from corrosion to the electrical system:

Significantly reduce magnesium and calcium chloride buildup during the cold weather by frequently washing equipment. Do not power wash as water can be forced into areas and cannot escape, leading to corrosion.

- Do not leave soap residue on electrical connections. When degreasers come into contact with electrical connections, it increases the corrosion reaction.

- Use a plug and socket brush with water (not soap) to clean connectors every six months, or more frequently in highly corrosive environments.

- Reapply dielectric grease on plug and socket pins to keep corrosion at bay after every cleaning.

- Inspect cables and wires for road-hazard damage such as cracks, cuts, and rubbing, and excessive butt connectors from an old repair. Wiring can wick moisture and additional corrosion might be present further up from the initial problem area. Replace or repair any damaged areas.

- If you must repair wiring harnesses, or any kind of wiring, use heat shrink terminals and/or heat shrink tubing with adhesive that seals the connection.

Knowing these rules will put you on the right path, but like with any successful marriage, just don’t forget to put in the work.

Fifth wheel maintenance tips

SAF-Holland recommends the following steps for its fifth wheel components:

- Lubricate the locking mechanism every three months or 30,000 miles.

- Thoroughly clean the locking mechanism every six months or 60,000 miles. Clean all moving components. Use of a WD-40 or CRC spray is recommended.

- Remove old grease and debris from all fifth wheel-to-trailer contact surfaces.

- Apply new water-resistant, lithium-based grease to all fifth wheel-to-trailer contact surfaces.

- Inspect for bent, broken, or missing parts every six months or 60,000 miles.

- Check the operation by locking and unlocking using a lock tester. Verify that the fifth wheel is completely closed.

- Clean and lubricate the locking mechanism if problems arise with coupling, uncoupling, or pulling the release handle.

JOST International maintenance recommendations include:

- Lubricate the kingpin lock using a hand pump grease gun through the grease zerk provided on the skirt of the fifth wheel.

- Apply a lithium-based grease with EP (extreme pressure) additive to the trailer contact surface of the fifth wheel.

- Apply a light oil to all moving parts.

- Every three months or 30,000 miles, inspect the mounting; repair or replace any missing or damaged fasteners or broken components.

- Inspect bracket pin bolts; make sure locking tabs are properly securing the bolts in place.

- Inspect the fifth wheel for bent, worn, or broken parts.

- Lock and unlock several times using a lock tester to check that the locking mechanism functions properly.

About the Author

Seth Skydel

Seth Skydel, a veteran industry editor, has more than 36 years of experience in fleet management, trucking, and transportation and logistics publications. Today, in editorial and marketing roles, he writes about fleet, service, and transportation management, vehicle and information technology, and industry trends and issues.