Ask the expert: How zinc coatings defend against corrosive winter chemicals

If last season is any indication, the coming winter will be exceptionally tough on commercial vehicles and equipment. It won’t be long before rain, snow, ice and sleet become business as usual for trucking fleets that frequent the northern regions of the country.

In areas where road salt and other de-icing chemicals are commonly used to combat icy conditions, corrosion protection is essential for trucks and equipment, as these chemicals can accelerate the formation of rust on the metallic components that comprise the chassis, body, cab, wheels and trailers.

This presents major challenges to fleets do to accelerated component breakdown, leading to higher maintenance costs and asset depreciation. To find out more, we spoke with Jamie Redd, PPG technical sales instruction supervisor, who provided insight on the challenge of winter conditions from a corrosion protection perspective—and outlined a very resilient solution. Below, he answers a number of important questions in anticipation of the next season of snow.

What is the cause of corrosion and the impact winter weather has on its development?

Corrosion is a chemical process through which metallic objects degrade and dissolve to create rust.

When trucks and equipment are exposed to excess moisture resulting from rain, snow, ice and sleet, they’re at an increased risk for sustaining corrosion damage, which can ultimately lead to vehicle and/or equipment failure.

Making matters worse is road salt. While it serves an important role in making roads safer for winter travel, road salt creates chemical reactions that speed up the corrosion process. Once the rust starts, it moves very fast.

What type of corrosion-resistant coating do you recommend for vehicles exposed to harsh winter conditions?

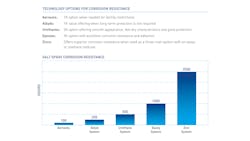

For a maximum level of protection, I suggest a corrosion resistant system that includes a zinc-rich primer. Zinc is a crucial ingredient because it acts as a sacrificial coating that prevents oxygen and water from reaching the steel substrate.

Even if the zinc coating is scratched off, it will continue to help protect adjacent areas of the underlying steel by forming a protective coating of zinc oxide.

You mentioned zinc as part of a system. What other components would this include?

Zinc would be your first layer of coating on a bare metal substrate. When using zinc in this application, it’s very common to introduce what is called an intermediate or “middle” epoxy primer. This will add extra protective qualities because it will help keep moisture from reacting to the zinc.

You’ll also want to use a high build urethane topcoat and a durable clearcoat. While using a clearcoat is optional, it will enhance the longevity of the substrate and help increase the longevity of the color from an aesthetics perspective.

Adding a zinc-rich primer to a corrosion-resistant coating system is a game changer. But can it be difficult to bring zinc into the equation?

There are a lot of zincs in the marketplace that can be complicated to work with. For example, a common option is a three-component zinc powder, which includes a curing agent and requires a lot of mixing and intensive agitation during application.

I can’t speak for all brands, but there are less complicated options, such as a system that features PPG ZNP-300 zinc rich primer. This two-component liquid primer is significantly easier to work with compared to a powder based zinc product. An alternate option is PPG ZNP-101 1K organic zinc rich primer, which is a one-component, ready-for-use product. A rule of thumb in this arena is that fewer components equates to greater simplicity.

Will these zinc-rich primer products work well as stand-alone primers?

Absolutely. When applied to an abraded or sandblasted substrate, both will provide excellent adhesion and outstanding corrosion resistance. But if you’re looking for a highly protective coating package to help maximize the longevity of vehicles and/or equipment exposed to harsh winter weather, consider using one of these two primers as your starting point.

For a middle coat of epoxy primer, I suggest the strong corrosion and chemical resistance of PPG CRE-X21 series primers. Follow this with PPG AUE-370 polyurethane topcoat, or equivalent, and round out your corrosion resistant package with PPG AUE-20 clearcoat, a high-gloss urethane clear that provides exceptional durability.

Will a zinc-rich system designed to provide a high level of corrosion protection come at the expense of appearance?

Again, I can’t speak to all the brands. However, I do know that with this PPG offering, you can get the benefit of extreme corrosion protection plus really good color capability and appearance. The key to this is the middle coat of epoxy primer along with the high-gloss clearcoat.

But I think the single greatest benefit of a complete system like the one I’ve described is the peace of mind knowing that you pretty much have to intentionally blast off the coating to get to the substrate. You’ll be hard pressed to match that level of protection with anything else out there.

About the Author

John McQuillan

senior writer

John McQuillan is a senior writer for the Group-eX agency and has been covering the automotive industry for more than 20 years.