Visual guide to commercial truck brake wear

April 18, 2023

2 min read

This guide provides various examples of drum and air disc brake issues due to wear and tear. See visuals below on common causes and corrective actions for issues that could affect brake performance and must be addressed.

Read more: Decoding the disc vs. drum brake debateAir disc brakes

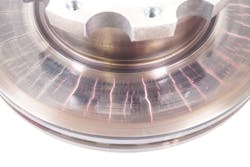

1. Disc Brake Cracking

- Damage: Cracks extending from one edge of the rotor to the other are not acceptable. Small radial cracks no larger than 1.5 mm wide and 1 mm deep are fine (as long as they don't extend across disc face), according to Bendix.

- Solution: Replace rotor if a crack reaches either edge. Circumferential grooving is acceptable as long as they are not too deep.

2. Guide Pin And Tappet Boot Damage

- Problem: Damaged or contaminated guide pin and tappet (piston) boots that cannot protect a disc brake to keep dirt, moisture and other contaminants from reaching other vital components.

- Solution: Check the boots for damage and contamination by pushing the caliper all the way inboard. Replace torn tappet boots.

3. Pad Surface Damage

- Problem: Major damage, excessive wear or glazing on the brake pads.

- Solution: Replace the brake pads.

Drum Brakes

4. Brake Pad Cracking

- Problem: Cracked brake pads

- Solution: Pads should be replaced immediately when cracks are observed. Consider the quality of the friction when choosing a replacement.

5. Thin Shoe Friction

- Problem: Thin friction in the middle of the shoe indicates uneven pad wear. Check for debris buildup or damage on the drum’s surface.

- Solution: Replace the shoes and examine the drum for any damage.

6. Raised Drum Edge

- Problem: A raised edge on the outside of the drum

- Solution: This indicates that low-quality hardware is being used. This drum should be replaced along with new and properly rated hardware.

7. Drum 'Leopard Spotting'

Problem: “Hot spotting” or “leopard spotting” on the drum is an indicator of friction that’s improperly rated for the vehicle.

Solution: Replace with a properly rated friction.

About the Author

Gregg Wartgow

Gregg Wartgow is a freelancer who Fleet Maintenance has relied upon for many years, writing about virtually any trucking topic. He lives in Brodhead, Wisconsin.

Sign up for our eNewsletters

Get the latest news and updates

Sponsored

Sponsored