Results from CVSA's 2023 brake safety event

The Commercial Vehicle Safety Alliance (CVSA) has released the results for 2023’s Brake Safety Week, which ran from Aug. 20-26. Throughout the week, inspectors examined 18,875 vehicles in the U.S., Canada, and Mexico, with a particular focus on brake pad and lining violations. According to the safety group, 12.6% of the total vehicles inspected were moved out-of-service due to brake violations

During the Level IV inspections, officers checked about half the CVs than in 2022 ( 38,117), with 87.4% exhibiting no brake-related out-of-service violations. The 2,375 vehicles placed out of service were due to violations such as broken brake drums, loose air tanks, corroded holes in the spring brake housing, inoperative tractor protection valves, cracked linings, loose chambers, or a combination of the above.

Of the vehicles placed OOS, almost 60% failed the 20% defective brakes criterion, with 1,127 out-of-service vehicles featuring stand-alone brake violations and 12.4% exhibiting steering axle brake violations. A total of 379 tractors and 261 trailers had lining and pad violations, highlighting 2023 Brake Safety Week’s focus issue.

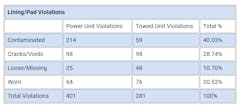

The focus on brake linings and pads further found that contamination was the most frequent issue with these components, with 214 tractors and 59 trailers logging contaminated pad and lining violations. The least frequent citation was for loose or missing pads, which accounted for 10.70% of lining and pad violations. In total, inspectors issued 682 citations related to these focus areas. In 2022, CVSA targeted brake and hose tube chafing violations, which totaled 6,305 violations.

CVSA recommended the following to improve brake lining and pad performance:

1. Inspect visible portions of the brake lining and pads as part of your pre- and post-trip inspections.

2. Look for signs of missing lining, such as grooves in the drum from rivet contact.

3. Look at the shoe-to-drum clearance and ensure there is adequate lining on the shoe.

4. Look for any signs of leaks from the hub or other components that may be contaminating the lining/pad surface.

5. Ensure there are no missing lining blocks.

6. Check for visible cracks or voids in the lining block.

7. Check for any exposed rivets or lining blocks that look loose on the shoe.

8. On disc brakes, pay particular attention to the condition of the rotor, such as heavily rusted rotors across the entire friction surface on either side or metal-to-metal contact.

9. Make sure all repairs are consistent with the brake manufacturer’s requirements and guidelines.

10. Note any issues in your driver vehicle inspection reports and report them to the motor carrier to have the defective linings/pads repaired.

For 2023’s Brake Safety Week, significantly fewer vehicles were inspected than in 2022, with 1,327 vehicles inspected in Canada, nearly 650 less than the year before, and only 9 vehicles inspected in Mexico. In the U.S., inspectors examined 18,031 vehicles in 2023 despite covering 34,402 vehicles in 2022.

Read more: CVSA's Brake Safety Day removed over 750 CMVs

Additionally, 397 of 2023’s Brake Safety Week inspections used performance-based brake testers (PBBT), which recorded 18 failures in total for a 4.5% out-of-service rate. 95 vehicles passed PBBT tests with at least one wheel below the 43.5% U.S. federal regulatory braking efficiency threshold.

The next Brake Safety Week is from Aug. 25-31, 2024.