ConMet eHub to power zero-emission reefer trailer

CLEVELAND, Ohio—With data showing heavy-duty trucking’s impact on greenhouse gas emissions and states such as California pushing stricter regulations, particularly on idling and transport refrigeration units (TRUs), ConMet’s eMobility group decided the best way to make an impact was by placing their Preset Plus Electric Hub technology into reefer trailers, effectively creating a zero-emission trailer.

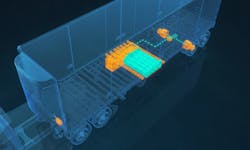

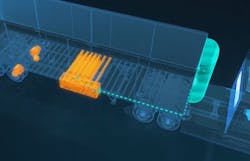

The regenerative braking energy captured from one set of the in-hub motors on the rear axle will be enough to charge the battery module under the trailer, which could then power an electric TRU or send electricity back to the hubs to assist in propulsion.

ConMet (Booth #6057) unveiled the solution at the American Trucking Associations’ Technology & Maintenance Council 2021 Fall Meeting & Transportation Technology Exhibition in Cleveland. The solution comprises two inhub motors integrated into the ConMet PreSet Plus hub assembly, a battery module and smart control panel. Replacing the diesel TRU system and additional diesel tank with the sustainable tech creates a net-zero weight gain.

Marc Trahand, vice president and general manager of ConMet eMobility, said the solution has the double-edged benefit of reducing fuel consumption in the TRU and truck engine.

“If you're pushing the tractor, we've seen up to 20% economy of diesel on the tractor itself,” he said. “So that is a huge benefit.”

ConMet estimated that a reefer tractor-trailer can save $7,500 annually, with 66% coming just by decarbonizing the TRU. Trahand noted how often reefers are parked outside of grocery stores just idling, burning fuel and creating emissions. Trahand noted there are about 500,000 trucks equipped with TRUs.

“The California Air Resource Board has taken notice of TRUs and they are looking at legislation in 2025 to ensure that TRUs are zero emissions, so we have to find solutions to do this—and time is getting really short.”

Along with lowering emissions, quieter operation, and reduced maintenance also help the total cost of ownership calculation.

If paired to an electric Class 8 truck, the regen braking could also extend range. The e-hubs can generate a peak of 156 kw.

“That means within minutes or hours, you can fill a battery with a high energy coming out of these hubs,” Trahand said. “It's way more energy than you could ever get from a solar panel on the roof. You can arrive at destination, and your reefer is cool, and your battery is full.”

The ehubs were first announced in 2019, and the last two years have been spent refining and readying the technology for commercialization, with more announcements on partners and future applications expected later this year.

“We really pushed the innovation there to basically make sure the design was modular, that it was fully validated, that we had good mechanical fit, and we were manufacturing for scalability,” Trahand said.

ConMet’s zero-emission trailer will be fully integrated into the CAN bus with smart controls deciding if and when the ehubs should be activated to assist in movement. The regenerative braking activates on hills and when braking.

“It's in sync with what the truck driver is doing,” Trahand said. “The torque inside the trailer is not going to be as strong as the torque inside the tractor, so you're not going to be in a situation where there's a huge push.”

ConMet vetted the technology in city driving, as urban areas are where TRU regulations would first appear. The company is also trying to improve ROI by making the technology available through various electric vehicle incentives.

“ConMet has been proactive,” Trahand said. “We're talking directly at the federal level, as well as the state level and different agencies to make them understand our technology, and how it needs to be included into incentives.”

Agencies contacted include the White House Council on Environmental Quality and CARB.

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.