The fleet maintenance industry has no shortage of data, and plenty of potential rewards to reap from harvesting that data, including greater efficiency and transparency. But sorting the wheat from the chaff in an endless data field can be tricky. So, how can maintenance departments find what they need?

"Go to your operations people and find out what you can do to help them do their job better," said Neil Roberts, fleet director at Raider Express, at the 2024 Truckload Carriers Association's Refrigerated Meeting. "There are vast amounts of data that you can pull from, but if you're not actually improving your operations and allowing your people to do their jobs and do them more efficiently, then the data is not very useful."

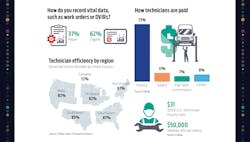

For maintenance departments, that can mean parsing through your fleet's historical data to find repair trends in the shop or comparing technician efficiency with repair costs to see if there's anywhere you can streamline your operations to save money.

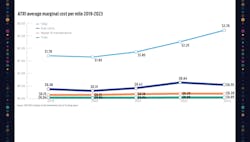

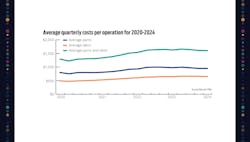

To help you do that, we've taken a broad look at the industry over the past few years, including data from the American Trucking Research Institute, Fullbay's State of Heavy-Duty Repair reports, and International Roadcheck results.

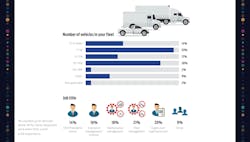

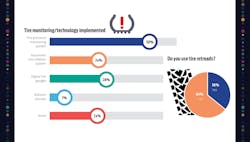

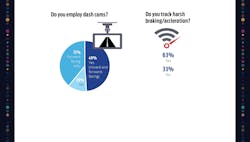

In October, we also sent out a survey to find out what our readers had to say regarding equipment and management practices. We received 58 responses and on the following pages, you can see what they said about current oil maintenance practices, brakes and tire trends, and the overall state of shop management. We hope it gives a clearer current view of the industry and makes your search for answers a little easier as you plan for the new year.

Demographics

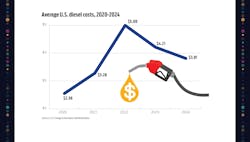

Oils & fuel

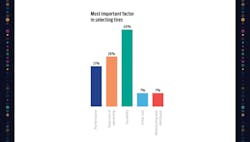

Tires & brakes

Other industry data/issues in the shop

About the Author

Alex Keenan

Alex Keenan is an Associate Editor for Fleet Maintenance magazine. She has written on a variety of topics for the past several years and recently joined the transportation industry, reviewing content covering technician challenges and breaking industry news. She holds a bachelor's degree in English from Colorado State University in Fort Collins, Colorado.

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.